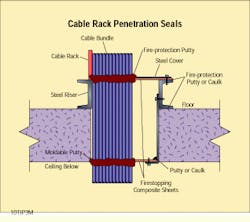

Installing cable rack firestopping seals

Dan Silver, 3M Telecom Systems Division

Problem

Cable racks that pass through concrete floor openings carrying telecommunications and power cables require firestopping seals with two-hour "F" and "T" (temperature rise) ratings as described in the American Society of Test and Measurement E814 standard. After you pull the cables through the floor into the cable rack, however, the hole and the gaps between the cables can adversely affect the fire rating of the system.

["F," or fire rating, determines that there will be no fire through the opening for the period of time specified by the rating. "T" is the temperature rise, not above 400F, in the same period of time. Ed.]

Solution

To restore the installation to its original fire rating, you will need to create a barrier to block the passage of flame, hot air, smoke and gases through these holes or gaps. One way to do this is to install cable rack firestopping seals.

Procedure

1) Assemble the materials you will need--composite firestopping sheets, fire-protection putty or caulk, large cardboard sheet (for template), marking pencil, sabre saw and mechanical fasteners.

2) Make a cardboard template of the opening by tracing around the opening and the cables. Using the template, trace the outline onto the firestopping composite sheet.

3) With the sabre saw, cut two firestopping sheets--one to fit in the bottom of the opening and one for the top. Make sure you cut the sheets so they will clear the cables: 0.25 to 0.5 inch between the cable bundle and sheet is acceptable.

4) Using appropriate metal fasteners, attach one sheet inside the bottom of the opening.

5) Press fire-protection moldable putty or caulking into the gap between the seal and the cables and all around where the sheet meets the floor or ceiling. Also work putty to a depth of 1 inch between individual cables.

6) Place the top seal using the same method.

7) If desired, an optional steel cover may be cut to fit over the top firestopping sheet to provide support for workers to stand on. Using mechanical fasteners, attach steel cover (if used) and the firestopping sheet together to the steel riser of the rack or to the floor.

8) Press moldable putty or caulk in the gaps between the cable bundle and the firestopping sheet and work the putty in between individual cables. Also press putty into the gaps along the back side of the seal and between individual cables to a depth of one inch.

9) You can also use moldable putty around the perimeter of the opening as a smoke seal.

Note: When a positive pressure smoke seal is required, each cable must be individually wrapped with a layer of putty before the top sheet is attached.

Dan Silver is market manager, local area networks, at 3M Telecom Systems Division, Austin, TX.

Use two firestopping composite sheets, moldable putty and caulk to fill the holes made by installing cables through the floor into a cable rack.