Help is on the way to meet the increased demand for Category 5 plenum cable

Barbara E. Thompson

As installers and distributors are aware, the demand for high-performance Category 5 plenum cable has increased faster than the supply. Prices have increased, too. The main reason for this shortfall is that Category 5 plenum cable requires insulation known as fluorinated ethylene propylene, or FEP, and the supply of this high-performance FEP has not grown as fast as the demand for cable (see "FEP Properties," page 56). As all the players work toward alleviating this shortage, the situation should improve in the latter half of 1995.

Installers are planning ahead on projects and, when appropriate, are using non-plenum cable. FEP suppliers are planning to increase production capacity, cable manufacturers are looking at alternative materials and design, and distributors are continuing to work closely with manufacturers and installers to meet cable requirements on a project-by-project basis.

The demand for Category 5 plenum cable is estimated to have grown 40% to 50% in cable-feet volume each year from 1992 through 1994, and cable manufacturers predict the demand will continue for most of 1995. DuPont (Wilmington, DE), manufacturer of Teflon (its trademark for FEP products), has increased production, but cannot predict how long the shortage of FEP will last.

"It will depend on how the market responds to the shortage," says Dan Kennefick, DuPont`s product line manager for Teflon FEP, Americas region. "The market will feed itself with something."

Installers are coping with the shortage in several creative ways, including keeping larger inventories, buying from more than one source, planning ahead and using non-plenum cable when appropriate.

For example, "When we first heard the rumor," says Len Campbell, field operations manager at Frontline Network Systems Inc. (Northboro, MA), "we went to a couple of our main suppliers and gave them blanket orders totaling 500,000 feet and asked them to stock it for us. We use about 120,000 feet of Category 5 a month, so a million feet doesn`t go very far."

In the past, installers have bought supplies from only one or two suppliers. "But we`ve diversified over the last couple of months and found other sources," says Campbell. "We`re buying all over now."

When the principals at Clawson Communications (Greenwood, IN) heard about the price increase and shortage of cable, they also started to stockpile cable. "We called our biggest customers about upcoming projects," says Karl Clawson, a principal at the company, "and we got verbal commitments from them. Then we bought a lot of cable." Planning is the key because, according to Clawson, lead times from some manufacturers are 10 to 20 weeks out.

Installers may have to shop around for Category 5 plenum. "My suspicion is that there is enough Category 5 plenum cable in the marketplace to satisfy needs," says Kevin Whitaker, marketing manager for local area network products at CommScope Inc. (Claremont, NC) "But I`m not sure that customers can necessarily buy the brand they want from the supplier they want to buy it from."

According to several manufacturers, installers should consider the following for the remainder of 1995:

Y Stay in communication with your cable supplier to ensure you have product allocated for your upcoming projects.

Y Do not use plenum Category 5 when non-plenum products will satisfy building codes and offer equivalent performance. Non-plenum has the equivalent electrical performance as a Category 5 plenum-rated cable.

Although installers are being proactive about cable, they cannot do anything about the shortage of raw materials.

Increased FEP production

DuPont is the major supplier of Teflon FEP products in the United States. Daikin America (Orangeburg, NY), the only other supplier of FEP for Category 5 plenum cable, ships its Neoflon FEP from its plant in Japan to cable manufacturers in the United States. The market demand has increased at a rate higher than FEP manufacturing capacity has been added. Both companies are working toward improving that situation.

"We`ve increased our production capability 25% per year for the past two years," says DuPont`s Kennefick. "Basically we`ve done it through improving yields and availability of product from our three plants." In addition, last September, DuPont announced its plans to expand its fluoropolymer capacity for co-polymer resins by 75%, a commitment of $150 million, through 1997. "We are putting major capital investment into our co-polymers, which is more than just the products we`re talking about here," explains Kennefick. "But a major portion of that support is for the tremendous growth in the U.S. wire and cable market."

Daikin`s Neoflon has approximately 30% of the FEP market for Category 5 plenum cable in the United States. "We`re out of inventory now," says Larry Galpin, Daikin`s vice president for sales and marketing. "Every pound we produce goes right out the door."

To increase its production of plenum-wire insulation materials, Daikin is building a plant in Decatur, AL, that is scheduled for completion in June 1995. "Assuming the startup goes fine, we will probably have commercial quantities of FEP starting about September 1995," says Galpin. "This will not substitute for our production in Japan; the capacity in Japan dedicated to the U.S. will continue, so this will be a positive increase."

If the production of FEP continues to increase, more raw material for cable manufacturers should be available later this year. In the meantime, what are manufacturers doing to meet end user needs?

Alternatives

The FEP shortage and the 10% to 15% price increase announced by DuPont last November are causing problems for cable manufacturers in allocating cable to their customers. Manufacturers are looking at alternatives to meet customer demands.

"At our Bell Laboratories," says Mike Barnick, product manager for high-performance LAN cables at AT&T Network Cable Systems (Norcross, GA), "we`re spending considerable time and resources looking at several different designs that expand the amount of footage with less materials, use of alternative materials or different combinations of those." According to Barnick, AT&T is evaluating several different prototypes and experimental products; however, it is "a little premature" to discuss them.

At General Cable Corp. (Highland Heights, KY), "we are protecting our customer base," says Kenneth McAllister, vice president and general manager for data communications/electronic products. "We limit orders to a mathematical function of the customer`s prior ordering history and other factors that won`t unduly penalize our newer customers. We have also increased production of non-plenum Category 5 cable to be used in conduit." McAllister says the company will also continue to evaluate alternative insulating materials.

Along with other manufacturers, Teledyne Thermatics (Elm City, NC) is looking at alternative products and compounds. "Something else we have done, however," says Ed Rattie, Teledyne`s director for network products, "is reduce our distributor base. We`re looking for long-term growth."

In fact, some distributors are selling to contractors or installers on a per-project basis. "Everybody`s stockpiling it [Category 5 plenum cable]," says Gary Lierman, director for advanced products at Wesco Distribution Inc. (Pittsburgh). "As soon as the product comes in to our distribution centers, it goes out immediately to our 200 branches. They want to make sure they`re not caught short," he says.

One reason for stockpiling is that it is difficult to get scheduled ship dates from manufacturers. "You place a large order and it comes in different quantities-in dribs and drabs," says Lierman. "It makes it difficult to plan."

When FEP is available again and manufacturers start shipping, those distributors and customers who have been stockpiling product may have problems. "But that`s not going to happen for a while," says Lierman.

Will there be enough FEP in 1995? "Certainly, it`s in tight supply," says CommScope`s Whitaker. "However, I think that everyone will be able to get enough FEP to get the main projects done, but there won`t be any left over. With more FEP coming in, that will alleviate some of the backlog problems."

Manufacturers and distributors should work together and these partnerships will filter down to the installer. Whitaker`s advice is "for everyone along the chain to communicate with each other, from end users to consultants to contractors to distributors to manufacturers. If everyone is communicating needs and availability, there may be some inconveniences, but at least we can eliminate surprises."

FEP Properties

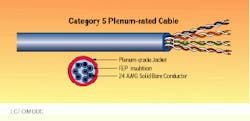

In Category 5 plenum cable, fluorinated ethylene propylene is used as an insulation on the paired conductors, which are cabled together. Then, a jacket is extruded over them.

[According to the 1992 edition of The DuPont Blue Book, the insulation stores electrical energy from signals passing through the cable. The lower the dielectric constant, the less the insulation distorts the signal. Teflon FEP has a dielectric constant of 2.1 at 1 megahertz.

Insulation also dissipates, or uses up, some of the electrical signal energy in the form of heat. Dissipation is one of the causes of attenuation. The lower the dissipation factor, the lower the attenuation.]

The properties that make FEP suitable for Category 5 plenum cable, as explained by Tim Berelsman, senior applications engineer at General Cable Corp., include:

Low dissipation factor across wide frequency and temperature ranges

Low and stable dielectric constant across a wide frequency and temperature range

Low smoke characteristics and flame retardancy required for plenum-rated cable

Good humidity stability

Suitable for thermoplastic-type wire extrusion.

"Other plenum-rated materials have one or two of the properties," says DuPont`s Kennefick, "but right now, there`s only one product that can be used as a wire insulation to meet Category 5 plenum requirements."

In Category 5 plenum cable, fluorinated ethylene propylene is used as an insulation on the paired conductors. Then, a jacket is extruded over them.