Mix and match success with Category 6 systems

There has been much discussion about interoperability since the introduction of Category 6 cabling systems. What is interoperability ? Simply stated, it is the ability to mix and match different manufacturers' components in a structured cabling system.

All of the history and development work discussed in this article resulted in and contributed to the recent publication of the ANSI/TIA/EIA-568-B.2-1 Category 6 standard in June.

In the beginning

Structured cabling existed long before the introduction of Category 6. The current entry-level of a structured cabling installation is Category 5 Enhanced (C5e). It is considered the minimum for Gigabit Ethernet deployment since additional tests have been devised that determine the installed system's ability to transmit on all four pairs in both directions, simultaneously. While the maximum operating frequency has not been increased beyond 100 MHz (the same as Category 5), the requirements at these frequencies have been modified. The limits for NEXT have been made tighter (less near end crosstalk is permitted in a Category 5e system than was in a Category 5 system).

Category 5e sets the scene for Category 6 and our discussion of interoperability. Interoperability is the mechanism used to ensure that all compliant manufacturers' jacks work with all other compliant manufacturers' jacks. While interoperability is an issue with Category 5e systems, as it was for Category 5 systems, the significant implications of meeting its requirements with respect to Category 6 require further explanation.

Category 6 cabling systems were introduced by ISO in September 1997, and these were quickly followed by the TIA. Category 6 differs in many ways from the Category 5 and Category 5e standards:

- It has a maximum operational bandwidth of 200 MHz;

- It's been designed to be tested to 250 MHz;

- It's available as a UTP and STP solution;

- It includes all of the tests of Category 5e, in addition to new parameters;

- ISO terminology for Category 6 permanent links and channels is Class E.

null

Early Category 6 developments followed very similar roads to Category 5 and Category 5e. The development of the Category 6 connecting hardware (i.e., plugs and jacks) was simultaneous. These two components were developed while connected together, or as a mated pair. Since there was no accurate way of developing an 8-pin modular plug or jack in isolation of its counterpart, this was an acceptable practice.

Unlike Category 5 and 5e, however, Category 6 involved more significant 8-pin modular plug and jack development. This led to a situation where, while the mated pairs of plugs and jacks complied with the requirements of the proposed Category 6 standards, the open system nature of previous cabling types was being eroded. The entire topic of interoperability concerns the development of both 8-pin modular jacks and plugs in isolation, using a method called de-embedding that will permit an open nature for all Category 6 cabling systems.

Field testing among friends

Since each manufacturer developed their own test plugs and jacks, and their system worked well, everything seemed to be progressing in the right direction. Field testing of Category 6 basic links was not a problem as most connectivity manufacturers were simply working with the field tester manufacturers to develop a basic link adapter that included an 8-pin modular plug configured to their requirements.

Initial Category 6 developments saw Manufacturer A's patch cord work with their jack, Manufacturer B's patch cord work with their jack, and so on. But little consideration was given to how Manufacturer A's patch cord would work with Manufacturer B's jack. In fact, in the early days of Category 6, mixing Manufacturer A and B could lead to performance levels that may only be to Category 5e or even Category 5 standards.

The implications of the recent Category 6 developments affected the field testing (permanent link) of installations as well as the future deployment of Category 6 active equipment. At the moment, no one worries about which Category 5e cabling systems work with which active hardware (i.e., hubs, switches, routers, and NICs). But once these devices begin to require 200 MHz of bandwidth to operate—that is, they need a Category 6 system—the absence of interoperability means that some manufacturers' connecting hardware would only work with a few specific active products.

It soon became obvious that market-wide interoperability was the only way to move forward with the development of Category 6 connecting hardware and patch cords. To meet this goal, a vast amount of effort was expelled in devising procedures to independently develop plugs (patch cords) and jacks that would operate with all other plugs and jacks, assuming that they, too, comply with the performance requirements.

De-embedding procedure

The introduction of reference plugs and reference jacks with the de-embedding procedure permits manufacturers to develop and then test their connectivity products to ensure that they will work with the reference plugs and jacks. If all manufacturers' connecting hardware works with the reference plugs and jacks, then it is safe to assume that they will work well with each other.

A TIA task group worked very hard to develop the specifics of the de-embedding procedure. The variations from test set-up to test set-up, from lab to lab, and even from test to test has made for a very time consuming development of de-embeddng. This procedure was one of the last points of contention with respect to the ratification of the Category 6 standard.

Both the real (magnitude) and imaginary (phase) components of the measurements are required to ensure that the plugs and jacks are compatible. Plug and jack performance values (both vector magnitude and phase) were determined, and compliance with these values is an indication that interoperability is achievable.

Reference plugs let manufacturers develop Category 6 jacks that will be interoperable. Reference jacks let manufacturers develop Category 6 patch cords that will be interoperable.

null

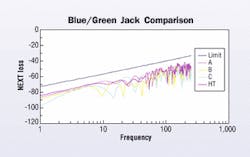

HellermannTyton performed various tests in the company's laboratory to determine if interoperability was possible. The graph above ("Blue/Green Jack Comparison") shows the NEXT loss comparison between four different manufacturer's Category 6 jacks placed into a single channel configuration—one after the other, each with the same horizontal cable and the same patch cords for all configurations. The closeness of the traces indicates a reasonable measure of interoperability.

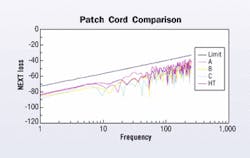

Another test ("Patch Cord Comparison," previous page) shows the NEXT loss comparison between four different manufacturer's Category 6 patch cords, placed into a single channel configuration—one after the other, each using the same horizontal cable and jacks. Again, the closeness of the traces indicates a reasonable measure of interoperability.

Permanent link testing

All certified installations of Category 6 systems require that a permanent link test be performed with a Level 3 tester. This test should, in theory, be a true test of the installed cable plant and exclude the effects of the cables and connectors that form part of the test equipment (these are known as permanent link adapters). The link adapters incorporate intelligence (in the form of a microchip) to calculate the effects of the adapter and cancel its effect on the test results. For those adapters to work with a wide range of manufacturers' systems, the interoperability issue becomes vital.

While considerable effort has gone into obtaining a tightly controlled range of 8-pin modular plugs from different manufacturers, not all manufacturers' hardware is compatible with all link adapters. The result is that any single link adapter may work with a number of structured cabling systems, but not all. The customer is then posed with the question, "Which tester can be used to certify a particular cabling system?," and "Would verification with another tester yield the same result?"

null

The field tester manufacturers' initially offered their testers with connecting hardware manufacturer-specific link adapters. This means that each cabling system has to have its own specific link adapter to perform the permanent link test required. This turned into a problem for everyone involved—tester manufacturer, hardware manufacturer, distributor, and installer.

The field tester manufacturers realized that there must be a better way to do permanent link testing for Category 6 systems. Most of the testers now offer standard or universal permanent link adapters that are supplied with the tester. This means that Category 6 connecting hardware must be interoperable with all these different link adapters—each adapter having a different manufacturer's plug on the end.

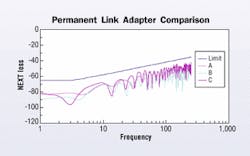

The graph above ("Permanent Link Adapter Comparison") shows the comparison between three Category 6 permanent link adapters, used to test a single permanent link. The closeness of the traces indicates a reasonable measure of interoperability and shows little variance from one tester to another.

Joys of compatibility

Our data shows that it is possible to have interoperability between well-designed Category 6 connecting hardware. It also shows that it is possible to have very little variance in field-testing of Category 6 systems among various Level 3 testers, as long as the components meet the TIA limits and are interoperable.

Category 6 systems need to be open in nature like Category 5 and Category 5e so that the industry will fully accept the technology.

(Note: All testing mentioned in this article was done with HellermannTyton's GigaBand Catgeory 6 system components.)

Jason James is director of technical resources, HellermannTyton, Northampton U.K., and Gary Bernstein is director of product marketing, HellermannTyton, Milwaukee, WI.