It pays to find the right connector technology

Improve your fiber connector installation, productivity, yields, and costs to meet your labor budget.

TIA-568B recently enabled optical fiber connectors in addition to the SC duplex, including the newly popular small-form-factor (SFF) designs. Along with these new interfaces came new technologies to promote quick installation. Quick, easy connections are essential to keeping labor costs low in optical-fiber installations.

Fortunately, options are no longer limited to heat-cured epoxies and hand polishing. Fiber connector manufacturers have come up with technologies to simplify the connectorization process and reduce labor costs. But, with this multitude of choices, selecting the best one for your application can be tough. Purchasing based on price or performance is a common practice, since these parameters are often used as selling points. However, a prudent buyer should also consider connector yield and installation time in order to make the best selection for the installation at hand.

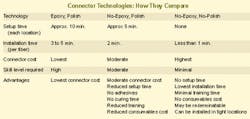

Keep in mind that connector technologies, not connector type, determine how the installation occurs. Therefore, as a basis for comparison, consider these factors when choosing connection technologies:

- Set-up time. This refers to the preparation time required before installing the first connector at a termination location. It may include getting out the necessary tools, setting up a polishing area, mixing epoxy, and filling up an applicator, if required.

- Installation time. The time it takes to install a connector on a 900-micron buffered fiber on stripped cable. This may include stripping the buffer, curing the epoxy, crimping, and polishing, as required.

- Costs. This includes the unit cost of the connector itself, plus whatever other materials are required to install it (i.e., consumables such as adhesive and polishing papers), any necessary tools, and labor.

- Skill level required. Some level of training is required for all connectors. However, technologies are now available that allow installers with minimal training to produce good results.

Regardless of the connector type chosen (most technologies are available for the common connector types such as MT-RJ, SC, and ST), it's important to maximize yield-ideally, 100% of the terminations made should test-out right the first time. This isn't always achievable, but it's an excellent goal. When yields fall significantly short of that mark, the amount of re-work required skyrockets, killing productivity and profitability for installer organizations.

Epoxy, polish connectors

Heat-cured epoxy was the first connector technology introduced and is still widely used today. This technique, which requires an oven and a 20-minute curing cycle, is best suited for terminating high-fiber-count cables (those with more than 24 fibers). When terminating large numbers of fibers, setup time is not a significant issue, because an assembly line process can be used to gain efficiencies. While some connectors are being polished, others are in the curing oven. The setup time can be "amortized" over a large number of terminations.

Today, faster curing adhesives are available that considerably reduce the curing time, often down to 2 minutes. Some adhesives even eliminate the need for an oven and its power source. Setup takes approximately 10 minutes because the adhesive and polish station must be prepared before starting. Installation time for one connector would take more than 30 minutes, but for more connectors, the time averages about 3 to 5 minutes per connector.

This method has the lowest cost for the connector itself, as it uses the simplest connector technology-just the connector pieces are purchased. But there are additional materials costs in the form of consumables (adhesive and polishing paper). It has the highest labor cost due to the required setup and installation times, and is not recommended for a fiber-to-the-desk installation as it is time consuming to setup the station at each work area.

The epoxy, polish technique is not difficult in principle, but it does require the most training and skill, specifically in the application of the adhesive and the polishing of the connector. These skills are easy to learn; however, they must still be taught and acquired, making this technique most suited to installation companies with a stable work force and low turnover rates.

No-Epoxy, polish connectors

No-epoxy, polish connectors replace the need for epoxy or other adhesives by using a crimping mechanism to hold the fibers in place within the ferrule. This type of connector is a popular choice for installers because it eliminates two of the industry's primary complaints: the need to mix and apply epoxy or other adhesives and the need for ovens, power, or ultraviolet (UV)-curing lights.

The amount of training and skill required is reduced since the crimp mechanism is easier to master than mixing and applying epoxy.

This technique is moderate in material cost. The unit connector cost is typically higher than that for epoxy, polish connectors due to the crimp mechanism inside the partially constructed connector, but this is offset somewhat by a lower consumables requirement (the need for adhesives is eliminated, but polishing papers and/or films are still required). By avoiding the use of adhesives, setup time is reduced, compared to the epoxy, polish technique. Setup time is about 5 minutes for the polishing station. Installation time is less, averaging 2 minutes per connector, most of that in polishing time. Again, the polishing station must be setup at each location connectors will be installed.

No-Epoxy, no-polish connectors

No-epoxy, no-polish connectors offer the easiest and quickest termination technology available. The installer only needs to strip, clean, and cleave the fiber before insertion into the connector. Inside these connectors are pre-polished fiber stubs that are already set in the ferrule. The connector body houses a mechanical fiber splice to hold the fiber being terminated in contact with the fiber stub. By eliminating the needs for adhesive preparation and polishing, setup time is likewise eliminated. Installation time is also the lowest (typically, about one minute per fiber).

This approach has the highest per-connector cost, as there is material investment in the splice and in the factory polish. However, this is usually more than offset by the elimination of setup time and the reduced installation time. Moreover, consumables costs, such as adhesives and polishing materials, are eliminated.

Without the tricky adhesive or polishing steps, installers require a minimum amount of training. There is also a technical or uniformity benefit to the use of this type of connector, since the end-face polish quality and the resulting return-loss performance of the connector is determined by the manufacturer, and not by the installers. Finally, it is easy to install these connectors in several locations, including cramped locations such as under a desk. Also, as an added benefit, the tools required for installation can fit in a small pouch.

Matching connector technology to the application

Considering the pluses and minuses of each connector technology, some patterns will appear:

Epoxy, polish connector technology is most suited to terminating large numbers of fibers in a single batch. It is therefore typically used in backbone cables-either campus or within building-and also at the telecommunications room when terminating many fiber-to-the-desk cables. This technology is not usually selected for fiber-to-the desk applications at the outlet or for low-fiber-count backbones as a result of the setup time.

The epoxy, polish technology is suitable for installers with low-labor rates and a stable, trained work force.

No-epoxy, polish connectors are ideal for locations with moderate fiber counts (12- to 24-fiber-count cables) or for companies that perform a mixture of backbone and fiber-to-the-desk projects. Many installation companies will find this connector technology also works well for high-fiber-count locations and for low-fiber-count applications such as fiber-to-the-desk.

No-epoxy, no-polish-type connectors are ideal for locations with low-fiber-count cables (less than 12 fibers), such as small building backbones or fiber-to-the-desktop applications. At the outlet, this technology offers significant advantages, as there is no setup time needed for a polishing station. In addition, only a minimal amount of excess fiber length from the outlet is required as there is no need to reach a stable polishing station-therefore, significantly reducing the amount of fiber that needs to be stored at the outlet.

This technology is ideal for installers with high labor rates and/or high technician turnover rates and those who do limited amounts of optical fiber terminations. Many installation companies choose the no-epoxy, no-polish connectors for small optical fiber projects-specifically, those involving small-fiber-count backbone cables (typically 12-fiber or less), where once again, reducing setup time helps them realize significant savings.

For the same reasons, no-epoxy, no-polish connectors are ideal for repairing, troubleshooting, and maintenance operations, as well as for performing moves, adds, and changes.

The choice is yours

Which technology or technologies you select will be determined by the requirements of your installations and your personal preferences.

There are no technical or administrative reasons requiring a network to use one technology exclusively throughout. Remember that the decision is not only one of performance but of installation and installer preference. Unlike the selection of the connector type, which is chosen by the customer, the selection of the termination technology should be made in consultation with the installation company.

But, don't forget cabling standards. Whatever connector technology is chosen, it's important to always use connectors that meet or exceed the requirements established by ANSI/TIA/ EIA-568-B.3, International Organization for Standardization (ISO-www.iso.ch) 11801, and EN 50173 for optical connectors.

Herbert V. Congdon IIis a professional engineer and director, Global Systems Marketing, AMP Netconnect systems, Tyco Electronics (ww.tycoelectronics.com).