The right firestop products for easier installation and retrofit

Finding the best technology for your specific voice and data cabling applications.

With the myriad of different firestop products available on the market, how do you choose the right one? Open the Underwriters Laboratories Inc. (UL-www.ul.com) Fire Resistance Directory and you will find at least 60 firestop manufacturers and more than 3,000 individual tested designs for various building service elements passing through fire-resistive-rated barriers, including floor/ceilings and wall assemblies. With all of these choices, how do you identify which product is the best product for a particular application? The purpose of this article is to provide guidance and information on product selection for applications involving voice and data cabling.

For most of us, the mention of the word "firestop" conjures up visions of red caulk being shot into all of the openings. In actuality, firestopping is a great deal more than just shooting red caulk into a hole. Firestopping is a system rather than just a product. A firestop system consists of: the barrier (the fire-rated wall or floor) being penetrated; the penetrating item (cables, conduits, etc.); and the firestopping products and design used to seal the opening. A little time spent in advance choosing the right systems will not only make your initial installation easier, but will continue saving the facility owner additional time and money with each subsequent cabling change.

Even that red caulk has its place. If you are installing cables or conduits in a permanent installation (one that will not require subsequent changes), a permanent firestop product such as a caulk or sealant could be the right choice. But in any telephone or data-intensive facility, the addition or removal of cables is an almost everyday occurrence. The wrong product choice in this environment can be a quandary that can cause headaches, not to mention lost time and revenues.

There are products and systems available that maintain the life safety of the structure, while facilitating quick, easy alteration of the cabling system. The most accommodating firestop systems are systems engineered with re-enterable firestop products. We prefer to recommend products that are "ready to install out of the box" without the need for cutting or alteration of any kind. Additionally, we prefer products that do not require tools or fasteners.

Let's review and comment on the products that are frequently used in telecommunications and data installations:

Firestop putty

Firestop putties represent a class of 100% solid, non-hardening products. They do not shrink, nor do they harden like most caulks and sealants. Putty excels in applications requiring subsequent changes after installation. Most firestop putties are intumescent products, meaning they will expand with heat or flames to help seal off combustible cabling jackets and prevent the spread of fire through fire barriers.

Firestop bags, blocks, or pillows

This category consists of non-curing products installed within openings that, just as the name denotes, resemble pillows, bags, or blocks/bricks. Firestop bags are loose-fill products that resemble beanbags. Blocks or bricks are typically composed of foam impregnated with an intumescent. Firestop pillows are simply intumescent cushions that can be compressed and stuffed into openings.

Firestop bags are the "granddaddy" of this product class. They were developed many years ago. These bags typically consist of a fiberglass bag with sewn seams, which is filled with a loose-fill product. While these bags look impressive and durable, there are some definite drawbacks to them, which have made these products obsolete with the advent of pillows and bricks.

Much like a box of crackers, the loose fill is subject to compaction. Loose-fill bags do not rebound when compressed, which translates into difficulty in achieving a tight seal during the initial installation and even greater difficulties when retrofitting. Since these bags are stacked atop each other and compacted down, individual bags at the cable interface cannot be removed without loosening the other bags. Thus, in terms of retrofit, the bags must be removed down to cable level and then reinstalled after each cable change has been made.

Firestop bricks or blocks are foam sponges that are stacked into an opening in a brick-like fashion. While they would appear to be relatively simple to install, they can present some significant challenges to the installer. The foam blocks have a high coefficient of friction. This makes them increasingly difficult to install as the opening closes down around the penetrants and up against the sides of the opening. The blocks also violate our basic tenet concerning "ready to install out of the box" in that some cutting of the blocks may be necessary in order to install them tightly around the penetrants.

Foams also have a tendency to fuse together over time, making removal or retrofitting a tougher chore. Be careful with foam polymer blocks that take a compression set when cooled. Some products will do this even at moderate temperatures-meaning that they may not re-install in an opening if the layout has changed in any way.

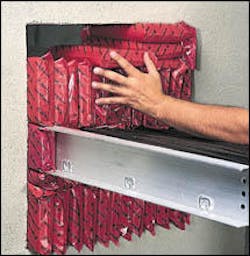

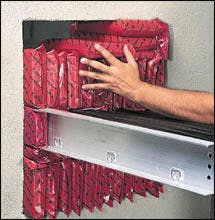

Firestop pillows were conceived to address the specific needs and challenges found in cabling applications. The concept was simple. If the product were easy to install, it would be easy to retrofit. This class of products meets our "ready to install out of the box" requirements in that no cutting, fastening, or compression tools are required. These products typically consist of a fibrous core material encapsulated in an intumescent coating protected by a poly bag. The fibrous core material is resilient. It will rebound after being compressed to tightly fill and seal all void areas. The poly bag is slip-finished to allow for easy insertion and removal. In cabling applications, retrofit is achieved by simply removing a single pillow at the cable interface. Due to the slip finish and compressible nature of the product, the same pillow can be re-installed without disturbing the rest of the firestop system. In the event of a fire, the product expands to form a hard-packed monolithic char that impedes the passage of fire, smoke, and combustion byproducts.

Many early UL systems utilizing pillows required that they be secured into the opening using a wire mesh. This requirement has been removed from many systems but may still be a wise choice in situations where the firestop is located in an exposed area subject to potential tampering. Pillows are the easiest and fastest product to install as well as the easiest to retrofit.

Composite boards

Composite boards are a popular firestopping product in the telecommunications and data markets. It consists of an intumescent rubber sheet sandwiched between a wire mesh and a layer of sheet metal. The composite board is cut to fit around a penetrant and fastened to the floor or wall like a lid or cover. While the installation concept is easy and the finished installation is attractive, composite board doesn't meet our "out of the box" truly re-enterable products criteria because a substantial amount of precise measuring, cutting, fitting, and fastening is required for the initial installation and each subsequent retrofit.

Composite boards really can't be used where there are a significant number of randomly placed or misaligned penetrants. We suggest the use of composite boards where retrofits will be infrequent or in those instances where appearance prevails over function.

Affordable options

Retrofittable products can be a bit pricey in applications where the openings are vastly over-sized. In these cases, we often recommend reducing the size of the opening using acceptable construction materials or a combination of firestopping products. For example, openings through gypsum wallboard that are excessively large can often be framed down using studs and gypsum board in a manner that matches the existing wall construction. In concrete or masonry walls or floors, several UL-classified systems for cable trays allow for the openings to be closed down using firestop mortar and just the area within and around the tray to be sealed with firestopping pillows. This design takes advantage of the economy of firestopping mortar and combines it with the retrofittable characteristics of pillows to give the firestop installer the best of both worlds.

What's the answer?

Of course, designing openings to be the proper size in the first place makes your job easier and less expensive. Since firestopping is a system, planning to seal the opening as you make it is the most effective way to do the job.

The purpose of this article is to provide guidance and information, not dictate a specific method. Having said that, when considering UL systems for cabling applications, one of the most important concepts to keep in mind is "installed life-cycle cost." The odds are you'll be back in that cable bundle, and probably sooner than you planned. The UL system that makes firestopping the easiest and most cost effective is the one you'll come to like best over time.

James Stahl, Sr. is the executive vice president; Raymond J. Bruno is the director of marketing; and James Stahl, Jr. is the engineering manager for Specified Technologies, Inc. (www.stifirestop.com)

null

Cabling Installation & Maintenance Story Ideas

Do you have an idea for a story on system design, installation, maintenance or troubleshooting? Send it to:

Patrick McLaughlin,

Chief Editor

Cabling Installation & Maintenance

98 Spit Brook Rd.,

Nashua, NH 03062-2801

tel: (603) 891-9222,

fax: (603) 891-0587

e-mail: [email protected]