Tested solutions solve problems in the field

Lab answers questions about electrostatic discharge and Category 5E OSP cabling.

How can you protect your microelectronic components from harmful electrical discharges? How do you use Telecommunications Industry Association/Electronic Industries Alliance (TIA/EIA-Arlington, VA) Category-rated local area network (LAN) cable to bridge between two adjacent buildings in a campus environment? Anixter Inc. (Skokie, IL), through its Levels Lab, has responded to these common inquiries by both customers and manufacturers alike.

Immense voltages

An electrostatic field is an example of pure voltage, or voltage without current. The strength of this electrical field is incredibly large when compared to the voltage of batteries and of common electronic circuitry. It can be hundreds, or thousands of times stronger. While somewhat counter-intuitive, everyday "static electricity" involves immense voltages. A tiny, yet detectable, "static spark" is caused by 500 to 1,000 V. It takes a 3,000-V charge to jump a 1mm air gap. Longer sparks, the kind obtained on doorknobs and refrigerators, involve 5,000 to 10,000 V. The most memorable type of everyday static electric discharge, sometimes called "car door sparks," have been measured as high as 20,000 V. Lightning is static electricity formed on a massive three- dimensional stage.

The scale of measure to determine which materials will most readily create this kind of electrostatic imbalance is called the Triboelectric Series. Human hands and manmade fibers (positive) are at the opposite end of the spectrum from polyvinyl chloride (PVC) and FEP/Teflon (PTFE) cable insulation (negative). The reeling and unreeling, handling and pulling of cable across tile and carpeted areas can create an imbalance of static charges.

The very nature of these dielectric materials makes them excellent for the storage of static charge, as an accumulation of charge will not move across their surface easily. It is important to understand that all cables, whether Category 3, 5, 5E, 6, or "plain old telephone service" (POTS), have a nearly identical ability to acquire a static charge.

Electrostatic induction

Reeled cable and service loops (installed loops of excess cable for future use) can act as induction coils. If temporarily stored, or installed adjacent to equipment that produces an electrical field, the cable can absorb a charge by induction. Examples of such equipment are large motors at the cable manufacturing plant, transformers in the receiving dock, photocopiers, and fluorescent lighting.

Capacitance

A capacitor is a pair (or series) of insulated electrical conductors, capable of storing an electrical direct current (DC) charge. The simplest capacitor is the Leyden jar (circa 1746), a glass jar with a thin sheet of conductive material pressed to its inside and outside surfaces. A Leyden jar no larger than a 35-mm film canister, can store a charge of more than 10,000 V. A capacitor is just one or more insulated conductors, isolated so as to hold a charge. Ungrounded indoor telecommunications cabling is a crude form of capacitor (and a crude antennae as well).

Threat to components

Electrostatic discharge can cause permanent damage and intermittent malfunction of components, sub-assemblies, and fully assembled electronic cards. That's why such cards are shipped in anti-static packaging. But even after they are installed, the port pins are a mode of entry to the circuitry.

Damage can occur at discharge voltages well below those that would be readily perceptible. The average individual can detect 3,000 to 5,000 V of static discharge, but component damage can occur at potentials of less than a few hundred volts. Static damage to semiconductor devices is dependent upon the device type and design, with fine geometry structures being the most susceptible. Damage sensitivities as low as 50 V may be experienced.

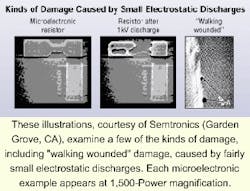

Devices may also be degraded by electrostatic discharges, without exhibiting an immediate failure of function. Such latent damage, often referred to as "walking wounded," (see illustration, p. 61) is more susceptible to future damage. Electrostatic discharge from cabling is not new, but the increasing density of electronic card circuitry in telecommunications is creating greater susceptibility, and bringing this old phenomenon under scrutiny.

Levels Lab proposes a solution

In Spring of 2000, Anixter's Levels Lab began an evaluation of the sources and potential problems of electrostatic charge accumulation via installed telecommunication backbone and horizontal cabling. The problem is of concern, primarily in regards to cabling that has been installed but not yet connected. Working with leading instrumentation and equipment manufacturers, Anixter's vice-president of technology, Pete Lockhart, approached ITWLinx (Harwood Heights, IL) to produce several prototypes of simple grounding devices for use with RJ-45-style patch panels. ITWLinx is a manufacturer of Underwriters Laboratories Inc. (UL-Northbrook, IL)-listed devices to protect equipment connected to voice and data lines. One of the resulting new products is pictured above. In use, the grounding wire lug is bonded to a grounded rack or cabinet, which is in turn connected to the building's Commercial Building Grounding and Bonding Requirements for Telecommunications (ANSI/TIA/EIA-607)-compliant grounding and bonding busbar network. Prior to connecting horizontal or backbone cables from patch panels to active electronics, a patch cord from the panel is inserted into the LAN Static Discharge Unit. Electrostatic charges are drained to the ground. Once connected to active equipment, there is no further build-up of electrostatic charges. Patents are pending on this solution.

Building data bridges

How do you use TTIA/EIA Category-rated LAN cable to bridge between two adjacent buildings in a campus environment? Anixter's Technical Support Group has received numerous inquiries about how to use Category 5 and Category 5E outside plant (OSP) cable in a campus environment. Here is a description of the problem and its Levels Lab solution.

Bridging on a budget

Cabling between buildings in a campus environment usually consists of fiber-optic inter-building backbone runs. But there are also numerous instances where the cable run is not specifically part of the backbone. Examples include: data cables run from a fixed building to a construction trailer; from the gym to the "temporary" Drivers Ed. simulation trailer; or from the parochial middle-school to the Rectory and Convent. In a small-scale industrial environment, such as a batch chemical plant, the runs might be from an engineering office to several plant operator huts and weigh stations scattered over a limited area.

In these examples, while good quality data connectivity is desired, it might not be economical to install and maintain a fiber-optic backbone. Until recently, a solution was not readily available. There was no TIA Category-rated OSP cable, and no category-rated provision for primary building entrance protection. So, the customary resolution was simply to use voice-grade telephone cable and telephone company protectors.

Protecting the OSP cable

But new products from two manufacturers can now be combined to provide a data cabling solution for this market-niche application.

Superior Essex (Atlanta, GA), a manufacturer of copper wire and telecommunications cable, produces a Category 5 OSP cable with 24 American wire gauge (AWG) conductors in 4-pair, 25-pair, and 100-pair configurations (and a Cat 5E cable is being developed). The cable designed for direct burial is a filled construction (spaces are filled with a water-blocking jelly). The conductors are MEGAPIC, plastic-insulated conductors for insulation displacement connection (IDC) termination, and the sheathing is the traditional OSP-coated aluminum under polymer-coated corrugated steel armor with a polyethylene jacket (CACSP). The cable designed for aerial applications is also a filled construction. Aerial cable con ductors are MEGAPIC, and the sheathing is the traditional OSP coated aluminum under a polyethylene jacket (CALPETH).

ITWLinx produces a 4-pair and 25-pair Category 5E primary building entrance protection module. The module is configured like a 110-block with IDC terminations and 66-block-style mounts. Twenty-five solid-state circuit cards connect to a backplane motherboard via pin and socket terminals.

Taking the direct buried route

As an informal overview of the process for providing a direct buried route, the following text is informative, but local codes and practices may take precedence:

- The easiest approach is to dig a slit trench to 6 inches below the local frost line. Fill the bottom of the trench with 3 inches of pea gravel. Bring the cable out of the basement of one building at a height of 6 to 12 inches above grade, and then down into the trench. Protect and anchor the cable to the outer basement wall with a "U"-shaped 4-ft cable guard and clamps.

- At the wall, cement the cable in-place and seal both sides of the wall penetration with waterproof mastic or ceramic wool and firestop putty. Treat the other building penetration in the same manner.

- The primary pro-tection modules can be previously installed inside at each end, and as close as possible to the cable penetration. A grounding lead should be provided from the nearest grounding busbar (refer to TIA/ EIA-607 "Commercial Building Grounding/ Bonding Requirements for Telecommunications"), or use a grounding rod arrangement.

- Cut back the polyethylene cable jacket, armor, and aluminum sheath close to their intended termination at the LAN protector. Leave at least 1 foot of unshielded twisted-pair (UTP) conductors free beyond the armor. Rinse the insulated conductors with a cleaning kit, or citrus-based cleaner, to remove the OSP waterproof jelly.

- Install a shield bonding clamp and ground bonding braid to the aluminum cable shield (and armor), and bond the other end of the braid to the grounded bus bar network or ground rod. Similarly, ground the protector using hardware supplied with it. These steps provide lightning safety protection to personnel and equipment. This applies to both ends of the cable.

- When complete, seal each end of OSP cabling with epoxy encapsulant, as with any gel-filled outside plant entry. Punch down the UTP conductors to the LAN protector. Indoor UTP Category-rated cabling may be used to continue on to the Main Distribution Frame.

- Next, backfill the trench with pea gravel until the cabling is covered, then cover it in black dirt. Tamp or allow settling before installing sod.

Below at left is an example of the typical materials required, presented in the form of an estimation worksheet.

Serving as an example

This estimation example is a Category 5 LAN-based data cabling solution, suitable for at least 10Base-T applications (and possibly 100Base-T, depending on length), and as described here, is part of the horizontal rather than backbone cabling. The distance limitation, therefore, is a total of 90 m (295 ft). The LAN primary protectors are not intended for the traditional ringing voltage of voice lines. Voice connectivity from the telephone company, key system, or small private branch exchange (PBX) would still require separate voice-grade OSP cable and traditional building entrance protection.

Due to the variety of applications and safety-related products described in this article, the user is responsible to assure each application and use meets performance and safety requirements, including any applicable laws, regulations, codes, and standards. Illustrations, charts, sample materials lists, and layouts shown here are intended solely for purposes of example.

Frank Dickman is an RCDD manager of technology for Anixter Inc. (Skokie, IL). He is the voting member for Anixter on behalf of customer interests at several standards development organizations.

Did these solutions spark an interest?

General information on static electricity, as well as experiments, schematics, and construction details for a 35-mm Leyden jar, and a "Ridiculously Sensitive Static Detector" can be found on the Web site of Electrical Engineering iconoclast William J. Beaty at www.eskimo.com/~billb/emotor/statelec.html.

Details of high-voltage "car door shocks" may be found in a paper presented to the Institute of Physics at a Static Electrification Group meeting in March 1998. The paper is entitled "The Control of Body Voltage Getting Out of a Car," written by John Chubb of John Chubb Instrumentation (Cheltenham, UK). It can be viewed at www.jci.co.uk/Carseats2.html.

Electrostatic discharge (ESD) summaries can be found in the EMC Journal U.K. archive at www.emc-journal.co.uk/archive1/protect~.html, including one by Brian Jones, referenced here.

Details and plans for various Leyden jars, including ones that will knock you across the room, can be found at www.alaska.net/~natnkell/leyden.htm.

Illustrations and a tutorial on static electricity, electrostatic discharge, and its effect on electronic chip components are provided by Semtronics Corp. (Garden Grove, CA), and can be found at www.semtronics.com/esd.htm.

Details of standards regarding electrostatic discharge may be found in documents from Global Documents at http://global.ihs.com and from the ESD Association (Rome, NY) at www.esda.org/. These standards include: the Commercial Building Grounding and Bonding Requirements for Telecommunications (ANSI/TIA/EIA 607); American National Standards Institute (ANSI-New York) EOS/ESD S6.1, "Grounding-Recommended Practice;" Electronic Industries Alliance (EIA-Arlington, VA)-541, "Packaging of Electronic Products for Shipment;" ANSI ESD S8, "ESD Awareness Symbols;" and ESD ADV2.0, "ESD Handbook," standards.

Published sources for OSP cabling installation details can be found in the BICSI Telecommunications Distribution Method Manual (TDDM) and Customer-Owned Outside Plant Design Manual at www.bicsi.org. The Customer-Owned Outside Plant Telecommu-nications Cabling standard (TIA/EIA-758) is available at www.global.ihs.com.

White papers, technical information, standards summaries, and international standards updates are available at Anixter's Web site, www.anixter.com.