Crimping tools: a tool belt 'must have'

Michelle Abrams

Cable, connectors, patch panels-it seems many of the ingredients are there, but how do they all fit together? Crimping tools are as essential to the building of a cabling system as an oven is to the baking of a cake. Without crimping tools, there is nothing to turn the parts into the whole. Needless to say, crimping tools are an essential to any tool belt. But what exactly are they?

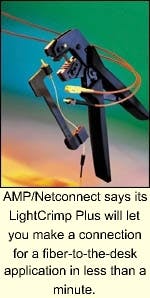

Herb Congdon, director of global systems marketing for Tyco Electronics/ AMP Net-connect (Harrisburg, PA), says they "started with the need to secure the connector body to the cable." The crimping tool sets the wires, or fibers, inside the connector, and/or the tool has a crimp body that holds on to the kevlar jacket. Additionally, Congdon says, "they are a necessity to strain relief the cables."

The art of the crimp

The act of crimping-attaching a connector to the cable-is accomplished with a tool appropriately called the crimping tool. The crimp head is the part of the tool connected to the two handles that fits over the modular connector to provide the crimping action. Die sets fit onto the crimp head and are usually made of steel, in block or plate forms, with small holes through which wire is drawn. Die sets vary based upon the type of connector being used, and are attached by screws to both the top and bottom jaws of the crimp head.

Plain and simple, crimping tools are a necessity. "They are a functional piece of equipment," says Jim Wasson, quality assurance manager for CompuLink (St. Petersburg, FL). Each tool used in CompuLink's premise design, installation and cable plant documentation activities must gain Wasson's approval. "For us, for creating LAN cords and patch cords for voice based networks, they [tools] work great," Wasson says.

Adds David Medeiros, technical support representative with The Siemon Company (Watertown, CT), "On the RJ-45 jack, there is really no other way to get the pins down than with the crimping tool."

These devices gained prominence in the industry hand-in-hand with the advent of modular jacks, yet have been around ever since cabling systems were first developed.

Les Shutts, engineering manager for Paladin Tools/Connectool Inc. (Ashland VA), dates the tools back to the 1800s. Some of the earliest crimping tools were pliers. While the need to attach connectors to cable is not a new phenomenon, Shutts estimates that the "modern ratchet crimping tool" came on the scene in the early 1940s and remains "integral to today's business."

Shutts adds, "Anyone in any form of wiring industry has to have a crimping tool." Without them, he says, it is virtually impossible to attach a connector in an efficient manner.

Although there are vast differences between the processes required for the installation of various mediums of cable, Shutts notes that "when it comes to the actual act of crimping itself, there is actually no difference." The difference lies in the connector and the die set used for that specific connector.

Painstaking preparation

The often cumbersome and time-consuming aspect of assembly is the preparation prior to crimping, notes Shutts. This often involves stripping the wire or polishing the fibers. "Crimping itself is actually a very fast process," says Shutts. The preparation involves a great deal of time, "especially UTP, that's the worst. It is slow and cumbersome."

But Congdon disagrees: "Typically, there are differences because the termination techniques are so different." For instance, he points out there is not as big a need for strain relief in copper connections as with fiber. Adds Akinora Ogawa, vice president of international sales at Tri-Net Technology (Walnut, CA), "Fiber cable requires more accuracy than copper and is more expensive."

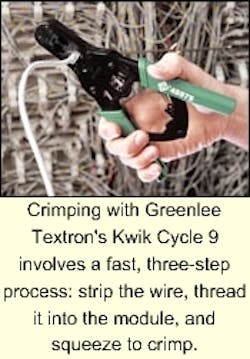

Crimping with the Greenlee Textron (Rockford, IL) Kwik Cycle 9 is a simple three-step process, according to Chera Ellis, the company's data signal voice product manager. First, the wire is stripped and then it can be threaded into the module. Finally, manual pressure is placed on the tool to complete the termination.

When it comes to actual crimping, Shutts believes that both coaxial and fiber require a one, maybe two-crimp cycle process while copper and standard computer cables require a one-crimp cycle. The Siemon Company's Medeiros agrees that the process is different depending on the medium, that when it comes to crimping, coaxial and UTP are "totally different scenarios." He claims the advantage of The Siemon Company's UTP crimp tools is their release latch. Once the crimp process has begun, Medeiros says, the release latch lets an installer disengage at mid-crimp.

Some would argue that the difference in crimping methods is actually the difference in connectors being crimped. An advantage of modern day crimping tools over the ancient tools of yesteryear is the interchangeable die set. "Some tools are universal in nature and can terminate both ST and SC connectors," says Congdon. This universal quality would not be possible without the ability to change die sets.

Switching between die sets is a simple process, explains Shutts. "It takes one minute," he says to remove two screws, replace the die, and then put the screws back in place. This process enables one crimping tool to crimp cable having multiple styles of connectors.

Wasson prefers to purchase crimping tools with multiple die sets that can accommodate both the RJ-45 and the RJ-11 connectors. This makes the tools both functional and cost-effective, he says. If he had to purchase one crimping tool for each connector, Wasson estimates he would be paying five times the cost of one, multipurpose tool.

From trend to necessity

Interchangeable die sets have, over the years, made the transition from "trendy" to becoming a standard on modern crimping tools. Ergonomics, durability, and multi-function capability have taken over the trend category. Ergonomic handles are being designed to prevent muscle strain and pain resulting for repeated use of the tool. But a number of these tools are constructed with handles meant to conform to a user's hand, with special grooves in which to place fingers. This design, however, is not suited for an installer with smaller or larger than average hands.

In response, Greenlee/Textron is moving to a design that features a one-groove handle positioning point, rather than a fitted handle, in an effort to provide comfort for various sizes. Ellis comments that installers are often "passionate about their tools," and accordingly, Greenlee/Textron is examining additional ergonomic and aesthetic variations that may enhance their tools' friendliness.

The need to make tools more durable is becoming increasingly important. For instance, Greenlee/Textron has revised its handle design. "We mold over the hard plastic a softer plastic," explains Ellis. "So, unlike other manufacturers, the handles do not fall off after multiple uses."

In Shutts' opinion, the ratchet mechanism "is the key to good crimp performance and tool longevity." Paladin's crimpers, he says, offer three parallel ratchet gear plates that aim to provide a longer ratchet life than tools with only one plate.

Manufacturers have also recently tried to meet economic needs by offering crimping tools with multi-function capabilities, primarily in the areas of cutting and stripping. Some multi-function products, such as one from Tyco Electronics/AMP Netconnect, can terminate multiple connector types, have crimp capability, and can terminate fiber.

Greenlee Textron's telephone ratchet crimper features both cutting and stripping mechanisms. Ellis observes that "Installers like it because the wire types are embossed by the cutter." CompuLink's Wasson, however, does not see these cutting and stripping functions as useful in today's market. "They are not good for round cable," he says, but rather are made for the flat, silver satin often found linking a telephone to a wall.

Outside forces

While the majority of crimping tools require manual force to accomplish the crimping action, there are some on the market that feature battery-powered, or other externally-powered forms of crimping. But "this causes the tools to get weightier," says Ellis. "And installers want to ease the burden on their tool belt.".

As an engineer and the inventor of the CrimpAll 8000 Series, Shutts points to several standards that must be considered when designing a crimping tool. For instance, Underwriters Laboratories Inc. has standards that must be adhered to for calibration. Additionally, there are ANSI/EIA/TIA standards which, according to Shutts, "specify the testing protocol for crimp tools."

Congdon, however, offers a different view: "It is not important to have standard tools but rather to have standard connectors," which he says will ensure interoperability with various cabling systems and will assure standards-compliant performance once installed.

Trying to sell specialized tools is a common technique used by manufacturers in an effort to increase sales. If their connectors are purchased, then additional revenue will be generated from the purchase of a unique tool required for the termination of that connector. For this reason, Congdon advises, "If I were shopping for a crimp tool, I would first shop for the connector technology and then buy the tool that goes with it."

Medeiros points to four integral factors that should be considered when selecting a crimping tool: interchangeable die sets; durability; dependability; and a disengage mechanism. He points to both The Siemon Company's UTP and coaxial products [See table, page 66].

Ellis suggests searching for tools that will be both economical and ease the installation process, while Tri-Net's Ogawa also suggests that "accuracy and economy" be considered. (Note that the price range for crimping tools is from $50 to thousands of dollars.)

Shutts says that installers should look for the best value-"anything that you can get the most universal use out of, has the best life span, and is affordable." In addition, Shutts predicts, "I think fiber is going to go to a different style of connector for quick termination." As connectors get smaller, Shutts says, he sees the necessity for new technology for terminations.

Crimping tools have clearly carved a permanent place in the cabling industry. But do not expect these tool-belt essentials to be stagnant. Opportunities are endless, industry experts agree, with the most prominent being the residential market. "Residential cabling installation is rising in the double digits and we see the opportunity," says Ellis.

null

null