Cabling carries a sweet tune at the Country Music Hall of Fame

Working in a Nashville landmark required an extra measure of skill and professionalism.

The latest addition to the Nashville, TN skyline is the new Country Music Hall of Fame and Museum. The 137,000-square-foot facility rises to 107 feet at its tallest point and is shaped in the form of the musical notation known as a bass clef. The rustic roots of country music seem to contradict the high-tech structure that includes a high-speed data network, interactive exhibits, several theaters, and a satellite radio-broadcast booth. The large, open building and varied cabling needs presented many challenges for Electronic Cable & Connector (EC&C), the cabling contractor on the job.

My firm was selected to pull the voice, data, and audio/ video cabling. Having been in the cabling-installation business since 1986, we have experience with a wide variety of infrastructures, including data, audio/video, and fiber optics. In fact, we "grew up" with twinaxial, coaxial, dual coaxial, Type 1, RS-232 and other cable types, all the way through Category 5e. So, we pretty much had seen it all, or so we thought. By the time we finished, the Hall of Fame project included more than 75 miles of low-voltage cable.

The Hall of Fame and Museum includes two interconnected buildings. The main structure houses the museum and exhibits, offices of the Country Music Foundation, a restaurant, and a gift shop. Approximately 300 feet in length, the building occupies the width of a full city block and has four levels. The smaller drum-shaped building houses the actual Country Music Hall of Fame in a second-floor rotunda, and also houses the Ford Theater on the first floor. The 225-seat theater is the setting for a video presentation for visitors, as well as special events and musical performances. (The engineers responisble for the acoustical design of the theater are the same professionals who acoustically engineered New York's Lincoln Center.)

Physical characteristics

The main building's first floor contains the restaurant, gift shop, security, and facilities management. The second and third floors each have a few offices, but primarily are dedicated to museum exhibits. The fourth floor contains the bulk of the office space, but even this floor is sparsely populated when compared to a traditional office building. The large size and low workstation density dictated much of the network design.

A fourth-floor computer room serves as the main crossconnect (MC) for the data network. Each level of the building has two telecommunications rooms (TRs), which are fed from the MC with a fiber-optic backbone. Berk-Tek 12-strand, 62.5-micron multimode fiber was used for the 100-Mbit/sec backbone, leaving the option for a future upgrade to Gigabit Ethernet. An Allied Telesyn 100Base-FX fiber switch drives the network. Other, 10/100-Mbit/sec switches, also from Allied Telesyn, with fiber-backbone modules serve the individual TRs.

The first-floor eastside TR serves as the demarcation point for telephone, cable TV, and Internet service. It also houses the telephone switching equipment. A 300-pair feeder cable runs from this point through EMT conduit to the first-floor westside TR, and to the second-floor eastside TR. From these points, 50-pair feeder cable continues up the riser to serve the floors above.

The voice trunk is punched down on 110 blocks in the main telephone room, but is punched onto Category 3 patch panels in the individual TRs. Patch panels for voice circuits accommodate the wiring system's "all-modular" design, which allows multiple uses of any outlet in the building. For example, you could patch to a 10/100 switch in the wiring closet to connect a PC to the network, or patch to the voice-system patch panel to connect a telephone. This design is also conducive to a possible future migration to Voice over IP.

Equipment specification

As a certified installer of Hubbell products, EC&C selected all Hubbell components for the installation. Three runs of CommScope Data pipe Category 5e 200 cable serve each workstation. The wallplates house three color-coded jacks. We used Hubbell SpeedGain 5e jacks to ensure the system achieved both channel and component compliance.

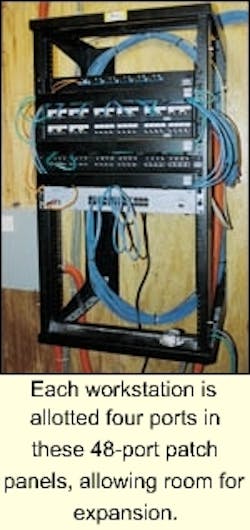

Forty-eight port patch panels from Hubbell's SpeedGain Category 5e product line are used in each TR. We set aside four outlets on the patch panels for each workstation, even though we wired only three, thereby allowing for growth and ease of labeling. Now each group of four outlets can be assigned a single workstation number, with colored icons to coordinate with individual jacks at the workstation end. The four-outlet grouping on the patch panel worked well in this scenario.

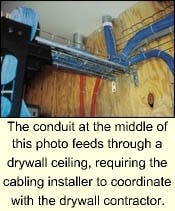

All TRs are linked with EMT conduit to support the riser cable. Unfortunately, the original drawings made no allowances for sleeving into the plenum air spaces outside the TRs to support the horizontal cabling. This was further complicated by several rooms that were specified to have drywall ceilings. EC&C came on board a little late in the game, and had to struggle to beat the drywall contractor into several of the TRs. EMT conduit sleeved through the drywall-ceiling space, into the plenum areas in the corridors.

These difficult contracting situations-which affect EC&C and companies like it regularly-are evidence that the engineer who designed these rooms could have benefited if the MasterFormat included a Division 17. Needless to say, EC&C could have benefited from a Division 17 as well.

Another difficulty with the communications wiring involved floor-mounted outlets, which were in place in conference rooms and several workstations. The specified poke-thru houses a duplex power outlet, but had only two small channels to route voice and data cable. The original design included no allowance for a data plate or jacks. Fortunately, two poke-thrus were specified at each location. EC&C recommended removing the power from one of the devices and dedicating the space to communications. Subsequently, a Hubbell 4-port 106 frame was used to house the jacks. The frame has the same footprint as a duplex power outlet, and can hold up to four jacks.

Audio-video cabling

The biggest challenges involved the audio/video cabling. Eight different cable types were necessary to accommodate the various signal types required. The Hall of Fame's A/V consultant, Electrosonic Systems of Minnetonka, MN, specified the design and the cabling.

Line-level audio required a two-conductor, 22-gauge shielded cable. The audio signal was provided to powered speakers and powered subwoofers at the exhibits. The same cable type was used for low-impedance audio feeds and microphones in the theaters, and links to the audio and video labs.

"We hope to be able to patch through live performances from any of the theaters in the building to the audio lab where we can record it," says Alan Stoker, audio archivist for the Hall of Fame. Stoker says he can send a taped audio signal back out to the theaters or to several other areas in the facility.

A two-pair 22-gauge shielded cable serves the needs of control and data transmission. Control applications include switches and relays at the exhibits. "This might be a push-button or a switch on a door that activates an audio signal when the guest opens it," says Electrosonic's Leroy Weibel. He also notes that this cable is used to send a more traditional data signal. "We use an RS-232 signal to control some of the automated projector screens and the count down clocks that announce showtimes," he says. "Some of the extended lengths in this building forced us to convert some of these signals to RS-422." Converters placed at each end of the cable run facilitate the conversion.

A 4-pair Category 5e cable was used for A/V network-type communications. Each museum guest wears a bar-coded badge around his or her neck while touring the facility. When the guest hears a favorite song at one of the listening stations, the guest can essentially "purchase" the song with a scan of the badge. As the tour continues, the guest can compile a custom audio CD that is ready for pickup at the gift shop when the tour ends.

The system that makes this custom-CD creation possible uses a traditional Ethernet network that is controlled by a server in the A/V control room. Network PCs with CD burners in the gift shop turn out the completed product. Several interactive exhibits also contain touch screens that require input from guests. These stations are also essentially network-enabled PCs.

Monophonic earphones located at some listening stations use a two-conductor 16-gauge cable. Intercom and small, low-power speakers use 2-conductor, 12-gauge cable. The large theater speakers were wired with 2-conductor, 10-gauge cable.

Pulling a large quantity of 10-gauge cable was a rude awakening for cable installers who are used to pulling 24-gauge Category 5e. "We used a cable tugger for some of the long pulls, but the size and weight of the cable made it difficult to handle when we had to string out a length of it," says EC&C job foreman Jason Woodard. "The big speaker cable came on 500-foot spools, so we had to be careful to keep track of what was on the spools. Several of the runs were longer than 300 feet, so we could only get one of those runs out of a single spool," he adds.

Pathway challenges

Pathways presented a significant challenge for the A/V cabling. All the ceiling areas in the exhibit area are open, so everything had to run through conduit. Once again, a Division 17 in the MasterFormat could have helped. Conduit fill ratios were stretched to the allowable maximum. A tight construction schedule also caused some problems with the conduit installation. In some cases, pull boxes were located above air returns or hard ceilings. In other instances, a fairly circuitous route was necessary to avoid obstructions.

Separate conduits for each cable type were routed to the individual exhibits. From the exhibits, the conduits were routed to the nearest TR. Then from the TR, four, 4-inch EMT conduits ran to the A/V control room.

"We wanted to avoid pulling the cables through the entire length of conduit," says Woodard. "There was also the problem of grouping. While each cable type had its own pipe running to the exhibits, many of them had to share the 4-inch pipes that run back to the control room." The installers had to bundle the cables according to type. The A/V contractor wanted to avoid any unnecessary interference, so the installers had to separate speaker and video cables from line-level audio and control cables.

Pulling the cable in stages solved the problem. The installers set up spools at the TR, and pulled cables to the individual exhibits. "We had previously measured the 4-inch conduits from the TRs to the A/V control room with a measuring type of pull tape," notes Woodard. This measurement was used to pull a length of cable off of the spools; the cable was then routed through the 4-inch conduit. Because these conduits were shared, all exhibits that routed through the TR had to be pulled before the similar cable types could be bundled and pulled back to the A/V control room.

"Since the quantity of cables was so large, we were concerned about pulling through a single pipe multiple times," Woodard continues. "So, we wanted to get everything pulled, and then pull them all back to the control room at one time." This approach left a great quantity of cable stretched out down hallways while the remainder of the exhibit cables were pulled. A lot of diplomacy was required, as the other trades and artifact movers had to work around the mass of cables.

Several parties learned a great deal during the Hall of Fame installation. But the best lessons learned were about dealing with people. As the cabling contractor, EC&C worked directly with the Hall of Fame. But on the job site, we had to work with and under the general contractor, and very closely with the electrical contractor who installed the conduit.

Ironically, or perhaps appropriately, the cabling job at the Country Music Hall of Fame required significant effort to achieve "harmony" with all trades involved. Constant communication with Electrosonic was necessary as A/V cabling needs changed. EC&C also worked closely with the building architect, telephone-system vendor, computer-networking consultant, satellite-radio professionals, security-system provider, cable-TV provider, and more than one telephone-service provider.

Once you get past the codes, specifications, and technical requirements, the cabling business-like most others-is still a people business.

Richard C. Lane, RCDD/LAN Specialist, is installation manager with Electronic Cable & Connector (www.electroniccable.com) in Hendersonville, TN.