FAA and Bostons MassPort give fiber the nod

FAA and Boston`s MassPort give fiber the nod

Officials at one of the busiest airports in the country upgrade the communications network with fiber.

Alyson Moore

Siecor

With 1700 inbound and outbound flights each day, Boston`s Logan Airport is considered a Level 5 facility by the Federal Aviation Administration (FAA--Washington, DC), which means it is one of the busiest airports in the United States. Between 3:30 p.m. and 6:30 p.m., as many as 120 planes touch down and take off each hour. FAA employees working at Logan are responsible for ensuring each arrival and departure happens like clockwork. Of course, their success hinges on the performance of the Massachusetts Port Authority (MassPort), which "owns" and maintains the airport. These two organizations work in concert with the goal of creating a safe and pleasurable experience for the flying public. With a massive cabling upgrade now under way at Logan, FAA and MassPort officials have one less thing to worry about--the reliability of their network infrastructure.

Completely recabling an airport is no easy task. In fact, it`s a logistical nightmare. Due to the nature of the information that is transmitted, no part of the system can ever go offline. Therefore, the decision to recable the airport is one that neither MassPort nor the FAA took lightly. Teams from both organizations evaluated their respective cabling plants and their ability to meet current and future networking requirements. They agreed that further copper upgrades would only delay the inevitable bandwidth shortage, and given the logistics involved in trying to upgrade a network with zero network downtime, they felt it was time to implement a fiber-optic system.

Once the decision to upgrade to fiber was made, a committee consisting of engineers and project coordinators from MassPort and the FAA was created. This Fiber Optic Network Technical Committee (FONTC) was tasked with developing training needs, budgets, and equipment and bandwidth requirements for both organizations. In addition, committee members were asked to develop an implementation strategy for the upgrade that would minimize disruption to the airport and the more than 65,000 travelers who pass through it each day.

Pooling resources

The project began in March 1998, but the FONTC will continue to implement and refine the system upgrade over the next several years; completion is not expected until 2002. A primary objective of both groups was to establish a dual-ring topology with self-healing nodes and a clockwise and counterclockwise rotating ring. A significant amount of infrastructure improvements was needed to accomplish this objective, but by teaming up, they were able to cut costs and consolidate requirements.

The decision to make fiber-optic cable standard throughout the airport not only ensured product compatibility, but also allowed both workforces to be trained at once so all the players from both organizations were capable of splicing, terminating, repairing, and maintaining any of the cable anywhere at the airport. MassPort and the FAA took it a step further by agreeing to use the same electronic interface equipment. Using joint supplies helped keep costs low and ensured that any restoration would happen quickly because at least one of the organizations would have spare products in its reserves. In fact, a whole system spare is kept at half of what it would cost if supplies were not shared.

Why fiber?

What concerned the FAA and MassPort was the harsh environment that their cabling infrastructure is forced to endure. Due to the nature of the data transmitted at Logan, signal integrity is critical. Fiber`s immunity to crosstalk and electromagnetic interference made it especially attractive for this application.

Security concerns at the airport also had an impact on the decision to use fiber-optic cable. Some of the information carried over Logan`s fiber-optic infrastructure pertains to the navigational aides and instrument landing systems. If anyone attempted to intercept this data, officials from the FAA and MassPort would know immediately. It is nearly impossible to tap a fiber-optic cable without the violation being detected.

Another benefit of fiber is that it is not subject to the same distance limitations of copper cabling. Bob Faherty, the FAA`s project coordinator for the New England Region, notes, "Copper`s distance limitations cannot get you from point to point on the airfield without a significant number of underground splices in a hostile environment."

In addition, the FONTC found that upgrading to fiber was more cost-effective than installing more copper cable. FAA and MassPort officials note that "fiber-optic communications systems have come down in cost and now compete favorably with copper systems." When they took into account the costs associated with an expansion to the existing duct system that would be required to add more copper cable, the cost model favored fiber.

After the network design was established, the project was put out to bid. Anixter came in with the lowest bid and won the project using a Siecor LANscape solution. A total of 142,000 feet (71,000 owned by the FAA and 71,000 owned by MassPort) of Siecor ALTOS cable containing 18 strands of Corning multimode fiber and six strands of Corning singlemode fiber runs throughout the facility.

Lightning strikes, de-icing compounds that are frequently required on the runways due to brutal Boston winters, and even the salt air coming from Boston Harbor can all wreak havoc on signals carried over standard-jacketed cables. To provide extra protection against jet fuel and de-icing chemicals, Siecor developed and applied a special aviation-grade nylon over the sheath of its standard ALTOS cable. Siecor SC UniCam connectors were used throughout the installation.

Mass Bay, a Boston cable-installation company, and Chappy Cort of nearby Chelsea, MA, were the contractors selected for the Logan Airport installation. Mass Bay hired Siecor`s engineering services department to provide support during the field installation. Representatives of the department were on-site when the cable was pulled, and Siecor engineers qualified the final installation, testing cable runs from the tower to the airfield.

The result of this coordinated effort is a fully redundant system with a dual-ring topology. If for some reason the FAA`s entire system were to go down, restoration plans would allow operations to continue operating over MassPort`s infrastructure. Conversely, if MassPort`s infrastructure went down, the FAA`s system would restore communications.

Sophisticated applications

Numerous communications systems throughout Logan Airport will be supported by the new fiber upgrade, and plans are in place to upgrade every FAA navigational aide by the 2001. The new fiber-optic cabling plant will primarily support air-surveillance radar equipment and several instrument landing systems.

The remote radio transmitter/receiver site, linked to the control tower via fiber-optic cable, allows air-traffic controllers in the cab of the tower to communicate with the terminal radar approach control room (tracon). The controllers that work in the cab are responsible for managing the traffic on the airfield, whereas the controllers that work in tracon manage planes in the air. As a plane approaches the airport, it broadcasts such data as its flight number, altitude, air speed, and origination point that allows the tower to identify each flight. This data is picked up on air-surveillance radar and transferred throughout the airfield via Logan`s fiber-optic cabling plant to the tracon room where the data is interpreted and posted on the terminal approach radar display.

The runway visual range (RVR) provides continuous electronic measurements of visibility based on weather conditions. There are three RVRs at Logan--the "touchdown," the "mid-point RVR," and the "roll-out RVR"--to monitor fluctuations in visibility at different points on the runway. This critical information regarding visibility is transmitted to the tower via fiber and allows controllers to keep pilots aware of the changing airfield conditions.

The very-high-frequency omnidirectional range radio, called the VOR, also runs over fiber. The VOR gives an estimate for the planes` directional approach to the airport and provides monitoring and control of visual navigational aides such as the precision approach-path indicators, medium-intensity approach-light system runway alignment indicator lights, and high-intensity approach-light landing system that provides visual guidance for nighttime and low-visibility landings. Fiber will also be the medium for the control of en-route navigation and terminal precision approach capability. This facility provides the aircraft`s VOR receiver with 360o courses for airway navigation.

MassPort will use the new fiber infrastructure primarily to run several systems designed to track changing weather conditions on the airfield. The runway weather surface detection system runs over fiber and serves as an ice sensor, providing continuous pavement evaluation--critical during long New England winters and hot summers. MassPort will also use fiber to run systems that monitor and control the various airfield lighting systems and a potential video system to monitor runway approaches and perimeter security.

The fiber upgrade will also support an airfield security system and the airport`s emergency communications network. The security system incorporates a key card access system that records and stores movement into and out of the complex. In addition, an emergency communications network links the airport fire department with rescue stations throughout the airfield.

Future plans for the new fiber-cabling plant include a surface-movement guidance-control system that MassPort plans to bring online. This system would provide pilots with a visual reference for the air-traffic controller`s instructions for taxiing around the airfield during periods of low visibility.

Most of the flying public have no idea of the sophisticated communications systems in place at airports across the country that make air travel possible and air traffic manageable. Nor do they realize the complexity of the systems required to ensure passengers arrive and depart safely and on schedule. All that most people care about is whether the systems work. Proper training of employees responsible for the maintenance of these systems is essential for passengers` peace of mind. To that end, Siecor provided a special training course specifically designed for airport personnel who will be responsible for operating and maintaining the new fiber-optic system. FAA and MassPort officials conclude, "Siecor provided continuous customer support by helping our engineers evaluate needs, providing excellent training and timely delivery of product."

Boston`s harsh winters and Logan Airport`s proximity to the Atlantic Ocean were two reasons network planners chose optical fiber for the airport`s network upgrade.

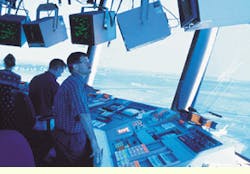

Air-traffic controllers in Logan Airport`s "cab" perform runway operations with systems dependent on the fiber infrastructure.

Alyson Moore is premises-market specialist at Siecor (Hickory, NC). Siecor acknowledges the contribution of Preston Buck, premises- market manager at Corning Inc. (Corning, NY), to this article.