Holocomm leads the way with open-office cabling

The company`s modular furniture system integrates furniture, cable, and termination hardware from any vendor.

Arlyn S. Powell, Jr. and Patrick McLaughlin

When you stop to think about it, the core cabling standards of the Telecommunications Industry Association (tia--Arlington, VA) were written for a different era. tia/eia-568a, the Commercial Building Telecommunications Cabling Standard, assumes a high-bandwidth backbone supporting telecommunications closets (TCs) on each floor of a building. Horizontal cabling runs to work areas originate in these TCs. tia/eia-569a, the Commercial Building Standard for Telecommunications Pathways and Spaces, indicates by its very name that it applies to architectural spaces--within rooms, behind walls, above ceilings, and below floors.

And yet, as most commercial and institutional office workers of the 1990s are well aware, the majority of today`s business activity takes place in cubicles with movable walls that are furnished with modular desks, shelving, and other office equipment. The tia recognized this business fact of life in mid-1996 when it published telecommunications systems bulletin tsb-75, Additional Cabling Practices for Open Offices. A tsb is an addendum document enhancing a full-fledged standard, in this case tia/eia-568a. tsb-75 specifies optional cabling practices for the open-office environment, identifying cabling and connection schemes that are easily modified when modular office furniture and movable partitions are frequently reconfigured.

Since the publication of tsb-75, there have been seemingly endless discussions at professional meetings about the relative merits of the multiuser telecommunications outlet assembly (mutoa) versus the consolidation point (CP)--the two wiring schemes specified in the document--but only over the last year have major new product and product-line announcements addressing the practical issues of open-office cabling appeared.

These practical issues revolve around the fact that modular furniture systems have an average lifespan of approximately 30 years, meaning that furniture due for retirement and replacement this year may have been acquired in 1970 or earlier, when a vastly different business environment existed. More than likely, there were typewriters rather than computers on most desks, and modular furniture was designed to carry power wiring and perhaps telephone lines. Issues around pulling tension and bend radius, which are important to today`s sophisticated fiber-optic and high-category copper cabling, were nonexistent, and separating phone and power lines to reduce interference was unheard of.

Today, these and other similar issues face designers and installers of premises-cabling systems when they plan those last, critical few yards to the individual workstation. No wonder then that following the adoption of tsb-75, cable and connector manufacturers should start to talk to modular-furniture makers about how such problems can be solved.

Pioneering the open-office system

Those discussions are now bearing fruit, with half a dozen or more major product announcements being made in the last half-year. But to one company--Holocomm Systems Inc. (Carlsbad, CA)--these products must seem like Johnny-come-latelies.

From 1994 to 1997, says Renney E. Senn, Holocomm`s president and chief executive, there was "as much awareness of this type of solution as there was to build a space shuttle--none." Lately, however, things have begun to change. "Cabling and the installation of it never held the importance it holds today," Senn states.

And therein lies the problem. Older modular-furniture systems are typically a hostile environment to cable. Cable bends can be sharp, cable can kink in furniture raceways, and abrasion and snagging are not uncommon on the burred openings where cable enters and leaves a partition. Category 5 cable subjected to these abuses may successfully carry data at the 10-megabit-per-second speeds most common today, but it is unlikely to perform well at 100 Mbits/sec--and gigabit-speed networking appears to be just around the corner.

Holocomm--"holo" being Greek for "all-encompassing" and "comm" short for "communications"--was born in 1994 when Senn and his partner, Tom Mitchell, now the company`s executive vice president, worked with a modular-furniture manufacturer to build a prototype wiring system to go in the manufacturer`s furniture raceway. The two men liked what they came up with so much that, a year later, they founded Holocomm Systems Inc., patenting a fiber-optic product in 1994 and a copper-wire system the following year. (The new system was first written up by Cabling Installation & Maintenance in the publication`s sister newsletter, Cabling News, in September 1995.)

How the system works

Unlike many competing systems, which depend on proprietary modular-furniture products incorporating specialized wiring and connection schemes, the Holocomm System`s TopRunner integrates furniture, cable, and termination hardware from any vendor. This integration is advantageous because existing furniture systems can be amortized over long periods of time and are not readily discarded by cost-conscious companies. Also, network managers develop preferences for and make investments in a wide variety of cabling systems; they are hesitant about changing to untried products when their existing cabling is preceived to be adequate for their needs.

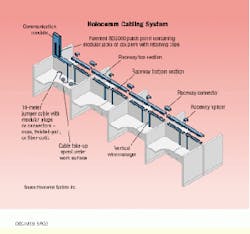

Here`s how the TopRunner system works: Cable is pulled from the telecommunications closet via ceiling, wall, or floor to a work area in the traditional way. On one of the panels in a workstation cluster, an assembly resembling a utility column is installed, running from the suspended ceiling to one of the furniture partitions. Within this column assembly is a patch panel, which is actually classified as a multiuser telecommunications outlet (muto). Connecting the muto to each workstation are 10-meter jumper cables, which run through a raceway-type piece that mounts on top of existing furniture panels. At the workstation, a covered vertical wire manager runs from the top of the panel to the desktop. Extra jumper cable is wound on a cable take-up spool mounted under the desk. The jumper is then plugged directly into the communications appliance without entering the furniture panels or terminating in a receptacle.

This approach offers many advantages to the end-user, according to Senn. "First," he says, "the top-cap distribution channel can mount to any modular-furniture system. Also, Holocomm custom-manufactures the mutos. Tell us how many fiber ports you want, how many Cat 5 copper ports, how many Cat 3 ports, how many coaxial ports, and that`s how we`ll build the muto. Furthermore, these ports can be easily reconfigured to accommodate any future cabling upgrades.

In addition, the end-user specifies the jacks to be used in the muto. Holocomm then acquires and installs the jacks in its custom patch panels. Since the customer buys the cable and specifies the connection scheme, and because the top-cap fits on any modular-furniture system, the end-user can be truly said to choose all components of the system.

Senn stresses that there are many benefits to the system in addition to its ability to accommodate all makes of furniture, cable, and connectors. "For instance," he says, "during a typical installation, the last two people on the site are the cabling installer and the furniture installer. This is traditionally a coordination nightmare. Cable installers pull to a certain point and then wait for furniture installers to put up panels. Then the furniture installers wait for the cable installers to pull cable through the furniture raceways. The furniture installers then put in the modular furniture while the cablers wait. And finally, the cable installers terminate and test the cable runs--all the while keeping their fingers crossed that the system will work."

Holocomm estimates that using its TopRunner system can save 40% of the time involved in a typical open-office cabling installation because far fewer coordinated steps are required. The cabling contractor can install and verify the network separately, before any furniture is installed, by putting in and checking the patch panels and jumper cables. Then the furniture installers come in and set up the furnished cubicles. And finally, the cabling installers return to install the cabling system on the furniture by adding the columns and top-caps and vertical wire hangers.

The company claims even more dramatic time savings for moves, adds, and changes--up to 90%, according to Holocomm`s Mitchell. "With traditional cabling," he says, "you make a $300 to $350 investment per workstation per installation. That investment must be repeated every time you move someone. With the TopRunner system, the investment is sharply reduced for every move" because of the simplicity of disconnecting and reconnecting workstations in differing arrangements: top-caps are snapped off, jumper cables unplugged, and patch-panel columns relocated.

And this benefit brings Senn to another advantage offered by Holocomm`s TopRunner system. "The whole idea of modular furniture," he says, "as evidenced by its name, is for it to be movable. But in reality, with today`s modular furniture systems you tie the units together by running cable through them." That makes it difficult to move a single workstation, or evena handful of workstations, and when such moves occur, the cabling in the partitions is pulled out and discarded.

Holocomm`s principals note other benefits to their system. Because of the home-run wiring scheme, individual workstations can be isolated and troubleshot without affecting the entire network--and 80% to 85% of network problems are specific to the workstation cabling, they say. In addition, this wiring arrangement offers no increase in the number of interconnection points--at the TC, at the muto, and at the workstation--which simplifies troubleshooting.

Pricing for the Holocomm system varies depending on the number of drops per workstation, but a typical installation of two Category 5 drops per workstation in a cluster of six workstations, permitting a 12-port muto, is about $300 to $350 per workstation, cost-competitive with conventional homerun methods.

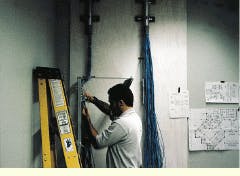

A cabling installer prepares a patch panel away from the work area.

Holocomm`s TopRunner modular-furniture cabling system consists of a unique patch panel and utility column, top-cap raceway components, vertical wire managers, take-up spools, and factory-connectorized jumper cables.

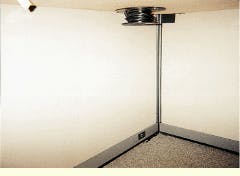

Part of Holocomm`s modular-furniture cabling system, this patch-panel utility column with faceplate removed shows the arrangement of the multiuser telecommunications outlet assembly.

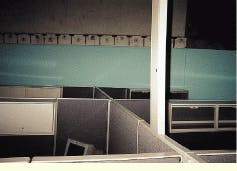

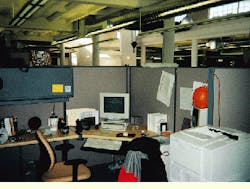

A finished installation with top-cap distribution system in place demonstrates how the TopRunner system blends in with existing modular-furniture systems.

Workstation areas are located at varying distances from the TopRunner patch panel, so a device is needed to take up slack and eliminate work-area cable clutter. A take-up spool is mounted for this purpose under the desktop.

Designed to blend with all popular brands of furniture, the top-cap distribution system and vertical wire manager running from it to the desktop are virtually indistinguishable from other modular-furniture components.