Modular fiber-cabling systems ease deployment

Use of multifiber connectors and mini patch panels may facilitate deployment of modular cabling systems.

Jean-Francois Cauchon

With the arrival of new multiple-fiber connectors and their use with preterminated patch panels, it is now possible for manufacturers to offer a more practical solution for easy and fast deployment of optical-fiber backbone cabling systems. Since several manufacturers are already offering this product type, it will affect the design and the installation of fiber-cabling systems and will determine the skillls needed to install them.

The future of the fiber-optics industry has never looked more promising than it does today. From the telecommunications marketplace to the data-communications premises wiring arena, all of the key players in the industry are experiencing tremendous growth in most of the business segments related to fiber optics. According to several market intelligence reports, the North American fiber-optic data-communications premises wiring market is expected to grow 30% to 45% annually for the next five years.

The quest for more bandwidth in the premises wiring market explains the growing trend toward obtaining fiber-optic components. Faster network protocols, more-demanding applications such as multimedia, and more-powerful computing resources have made the attainment of additional bandwidth a growing need and a great challenge for today`s information technology managers. In light of this trend toward higher bandwidths, optical-fiber cabling systems offer the ultimate "insurance policy" against obsolescence of a cabling system because of their ability to support high-bandwidth applications.

Another factor that favors the use of fiber optics is the reduction in the cost and installation complexity of fiber-optic components. New technologies in fiber termination and improved manufacturing processes are driving down the cost of fiber- optic components and making installation procedures easier than ever before.

History of fiber-optic deployment

Fiber-optic deployment, throughout its recent history, has always consisted of the same two general operations. The first is deployment of the fiber cable, which can take several forms, such as pulling through conduits, direct burial, and aerial deployment. The second operation is termination of the fiber cable, which can mean fusion or mechanical splicing, epoxy/ polish-type connectors, epoxyless/no-polishing fiber-stub connector technology, ferruleless connectors, and testing.

Over the past couple of years, the fiber-optics industry has focused most of its efforts on developing products to facilitate the termination process, which is the more important, time consuming, and expensive operation of the two. These efforts have resulted in numerous changes and innovations in the field termination process. These include field-mountable connectors, quick-curing epoxy-type connectors, no epoxy/no-polishing fiber-stub connector technology, improved tool kits, and new fusion-splicing sets. All of these enhancements have been aimed at reducing the cost, the amount of time, the expertise, and complexity involved in the fiber-cable termination process.

Fiber-stub technology, in particular, has removed the difficulty and uncertainty that installers have faced when attempting to cure epoxy and polish ferrules. This technology consists of a fiber stub that is factory-installed in a ferrule, factory-polished, and embedded in a gel-filled mechanical splice.

Even though the field termination process is becoming easier, it still requires a fair amount of training, expertise, and dexterity, as well as some basic tools. Even with the best tools and instructions, a small percentage of installers will stay away from deploying fiber-optic components. Moreover, none of these innovations address the time-consuming and difficult task that is involved in testing the results. New tools, such as the optical time-domain reflectometer, have been developed to facilitate the testing process; nonetheless, it still remains a very lengthy procedure, during which minor errors can force installers to reterminate a good connection or to accept bad ones.

Not so long ago, some of the major manufacturers in the fiber-optics industry came up with a clever idea: Use fiber cables that are preterminated and tested in the factory. This would rid installers of the uncertainty, time, and complexity associated with the termination and testing procedures otherwise necessary when installing connectors.

Several manufacturers offer custom, preterminated cable assemblies that are equipped with "pulling eyes." These products allow installers to benefit from quick deployment of fiber-backbone cables; they require very little skill and no special tools. The only problem related to this alternative is their bulkiness, which makes them difficult to fit through conduits and feed through fiber patch panels. With preterminated cable assemblies, the installation difficulty shifts from the fiber-termination process to fiber deployment.

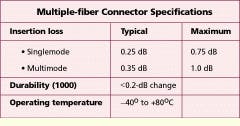

The latest development in fiber-optic technology came with the advent of a new type of connector: the multiple-fiber connector. This new connector uses a special rectangular ferrule that can accommodate six to 12 singlemode or multimode fibers. The design is asymmetrical and the male and female connectors mate in a special adapter. The male connector has two metallic guide pins that mate accurately in the female connector, allowing for a perfect alignment of the 12 fibers.

Another feature of the multiple-fiber connector is its size. The connectors (male or female) have a width of approximately 0.5 inch (12 to 14 millimeters).

The advantage of multiple-fiber connector technology has become obvious with the development of the latest generation of fiber-deployment systems. This generation of products is now replacing the preterminated cable approach by eliminating most of its shortcomings. In fact, the size of a multiple-fiber connector (male or female) makes it ready to be pulled, with the use of a pulling kit, through a 3/4-inch conduit.

Besides taking advantage of multiple-fiber connectors, modular cabling systems also introduce a new concept in fiber termination--a ruggedized, compact fiber patch panel that contains six to 12 preterminated connectors. The combination of these two innovations provides a very fast and easy way of deploying a fiber-optic cabling system.

Cabling installers also have a choice of configurations when using modular fiber-cabling systems: the "economical" configuration or the "flexible" configuration. The economical configuration uses only one multiple-fiber connection. It consists of a mini patch panel with 1 meter of ribbon cable terminated with a multiple-fiber connector at one end. A second mini patch panel with a long (custom-length) fiber cable is terminated with a multiple-fiber connector at the other end.

The flexible configuration enables the cable to be pulled from either or both ends (provided a pulling eye is attached to both ends). It consists of two mini patch panels, each equipped with 1 meter of ribbon cable terminated with a multiple-fiber connector at the other end, and a long (custom-length) piece of distribution cable preterminated with multiple-fiber connectors at both ends.

The mini patch panel usually comes preloaded with the following types of connector: ST-compatible, SC, and FC. Most of the modular fiber cabling systems offer multimode- and singlemode-fiber deployment.

Features and benefits

The main benefit of the modular fiber-cabling system is the savings in installation time and the cost reduction in the overall deployment project. During field applications, there is a definite reduction in installation time when deploying a modular fiber-cabling system rather than a conventional fiber system.

For example, let us take a 100-foot installation with a typical 24-fiber backbone with ST multimode connectors at both ends in a conventional 24-port patch panel. This complete installation would take no more than 15 minutes with the modular approach. If we compare the overall cost of a fiber-deployment project that includes labor and equipment, the modular fiber- cabling system would end up being the more cost-effective method, since the labor part of the project is sometimes cut by more than half. Some of the benefits include:

-extreme simplicity, which reduces risk

- factory termination, which provides time savings

- factory testing, which ensures reliability

- the fact that no special tools are required, which reduces initial investment

- the elimination of the need for special skills or training, which reduces costs.

Application and new opportunities

Whether employed in a simple 6-fiber backbone or a complete fiber-to-the-desk solution, modular systems offer flexibility and ease-of-use in any situation that requires fast deployment, such as backbone terminations in telecommunication closets, horizontal distribution, consolidation points, equipment racks or cabinets (19- or 23-inch), and wall-mounted applications.

In addition, new opportunities that could not be addressed in the past with conventional fiber-deployment methods are now being presented to the fiber-optics industry. Fiber-deployment projects no longer require significant expertise and craftsmanship. Projects can be turned around more rapidly because of the significant time savings in the different steps of a project, including the bid process, component supply and job scheduling, cable installation and area preparation, mounting hardware, the cable-termination process, patch-panel termination, testing, and cleanup. New opportunities that could be addressed by modular fiber systems include temporary sites (trade shows and conferences), emergency and recovery scenarios, military applications that require fast and temporary deployment of fiber, docks and ships, and mobile units.

In conclusion, a modular fiber-cabling system is a simple and clever idea that takes advantage of two recent innovations: multiple-fiber connectors and mini ruggedized patch panels. This modular approach relieves installers from the uncertainties, difficulties, and costs that are involved with fiber termination and testing. The overall cost of such a project is greatly reduced because the labor costs incurred with conventional fiber methods are also significantly reduced. Furthermore, new opportunities are accessible to cabling specialists who do not have expertise in fiber-optic termination or testing.

This ruggedized mini patch panel with 12 ST-compatible connectors illustrates the combination of a custom fiber cable with a factory preterminated patch panel at one end and multifiber connector on the other.

The "economical" configuration uses only one multifiber connection.

The "flexible" configuration uses multiple connectors and can be pulled from either end.

Jean-Francois Cauchon is product line manager for the nordx/ cdt Fiber Optic Div. (Pointe-Claire, QC, Canada), a subsidiary of Cable Design Technologies. This article is reprinted from the July 1998 issue of Lightwave magazine, another PennWell publication.