A new model for multimode fiber qualification

Mark Johnston

Microtest Inc.

The U.S. market for multimode fiber-optic cabling in data-communications applications is growing. In fact, Kessler Marketing Intelligence Corp. (Newport, RI) estimates that the market in this country is growing at a compounded rate of 20% per year and will exceed $1.45 billion in 2001.

This growth is driven by two factors: traditional concerns about fiber--cost and difficulty of handling--have significantly improved in the past two years, and the benefits of fiber for data-communications applications are becoming increasingly important. Key benefits of fiber over copper include complete immunity to near-end crosstalk and background noise, greater transmission distances, and higher bandwidth.

The increased use of multimode fiber-optic cabling is at least partially due to the increase in computer networking. As networks become more mission-critical, the quality, robustness, and future capability of the physical infrastructure have become correspondingly important. While fiber is still more expensive than Category 5 copper solutions, the cost premium in some cases is justified by fiber`s natural advantages.

Qualifying copper and fiber

The requirements to qualify a Category 5 link and the requirements to qualify a multimode fiber link also illustrate differences in the media. For Category 5 cables, new standards such as telecommunications systems bulletin tsb-67 issued by the Electronic Industries Association and the Telecommunications Industry Association (both in Arlington, VA) have evolved, new measurements such as propagation delay and delay skew have become necessary, and new products have been introduced to simplify and automate what is a complex qualification process.

To certify a Category 5 link, you must measure length, attenuation, near-end crosstalk, wire map, propagation delay, delay skew, and impedance. You must repeat many of these measurements on all four pairs, and make the measurements in a sweep fashion from 1 to 100 megahertz, meaning thousands of measurements. Also, requirements for measuring return loss, far-end crosstalk, balance, power-sum near-end crosstalk, and screening effectiveness--all at frequencies higher than 100 MHz--are under consideration.

Qualifying multimode fiber, on the other hand, is simpler. You measure attenuation at 850 and 1300 nanometers in the direction of transmission. If neither length nor delay requirements for the application have been exceeded, then the job is done.

Perhaps because fiber testing is so straightforward, test tools and processes have changed little in the past five years. But while testing multimode fiber is simple, today`s tools can make the process time-intensive, because with fiber, attenuation must be measured in the correct direction--unlike copper. Attenuation in copper cables is symmetric, so the result will be the same regardless of the direction in which you test. However, with fiber, you must measure attenuation in the direction of data transmission because the attenuation is asymmetric. The loss in the PC-to-hub direction is different from the loss in the hub-to-PC direction on the same fiber.

Historically, installers have had to complete the following 12 steps to measure a fiber pair:

-Connect and run the test at 850 nm.

-Store or write the results.

-Switch connectors to 1300 nm.

-Run the test again.

-Store or write the results.

-Walk to the other end of the fiber.

-Connect and run the test at 850 nm.

-Store or write the results.

-Switch connectors to 1300 nm.

-Run the test again.

-Store or write the results.

-Walk to the starting point.

Considering the need to test fiber in the correct direction, the approach described above has four obvious inefficiencies. First, the operator must walk back and forth to measure loss in the right direction. To save time, many installers test from only one end and have questionable results for half the measurements. Second, the operator must constantly change connectors to switch between 850- and 1300-nm source wavelengths. Third, because fibers are tested in pairs, it is inefficient to test them sequentially, considering that with copper cables all four pairs are tested simultaneously. Finally, the recording and management of data is often manual and error-prone.

Analyzing test results

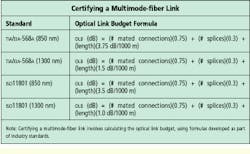

The optical link budget presents another concern for fiber installers. Cabling standards provide guidance regarding how much loss is permitted at each wavelength. Permissible attenuation values are based on the length of the link, and the number of splices and mated connections. This consideration differs from copper-cable testing, in which pass/fail measurements are constant, and testing instruments can indicate whether a link passes or fails based on the values alone. When testing fiber, the user must determine how much loss is permitted in each link. It is not possible to simply run a test and know whether the attenuation level is acceptable, without knowing the wavelength, number of connections, number of splices, and fiber length.

Technology has opened the door to more-efficient multimode-fiber testing. A fiber tester is now available that tests both fibers in the pair, in the correct direction, at both wavelengths simultaneously, and also measures length and propagation delay. Users can also input the number of splices and connections in the link into the tester, which then computes the optical link budget and provides a pass/fail analysis. It also certifies whether the link is suitable for network-specific fiber applica- tions such as 10Base-F, 100Base-F, 1000Base-F, Fiber Distributed Data Interface, and Fibre Channel.

Use of this tester collapses the 12 steps previously necessary to 2:

Connect and run the test.

Store the result.

The tester time-stamps and gives alphanumeric names to as many as 1000 fibers, stores them internally, and can download them onto a PC.

This technology provides several advantages for installers, including speeding up fiber testing, providing information such as length and propagation delay that were previously available only through an optical time-domain reflectometer, and providing professional certification reports.

A fiber-optics market research firm estimates the U.S. market for fiber-optic cables will exceed $1.45 billion in 2001.

Mark Johnston is director of technology development for Microtest Inc. (Phoenix, AZ).