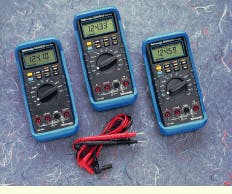

Digital multimeters close the safety loop

Karen Graziano

If you`re looking for a small, fast, and inexpensive testing device to measure capacitance, continuity, current, resistance, and voltage, then you`re in luck. Manufacturers are offering a plethora of digital multimeters (dmms) that fit the bill. In addition to instant testing, dmms offer accuracy, reliability, and ease of use as standard features (see Product Update table, page 124).

Manufacturers are now tailoring dmms to fit niches within the cable-testing market, so installers can purchase a product with as many or as few functions as needed and with a price that corresponds to these features. When you are choosing a dmm, aesthetics such as shape, feel, and size are also becoming distinguishing factors. "When installers look at a product, they are looking for the ergonomic shape and the readability of the display," says Paul DeWinter, product support specialist at Wavetek Corp. "Manufacturers are considering how the meter will feel to the user and how easy it is to use."

Test-equipment manufacturers are concentrating their efforts on dmms because these testers are becoming a necessity in installers` toolboxes. "Many years ago, in the central office, where your switching capabilities are located, after someone dialed a number, the meter would interpret it and then make the connection. It was a wonderful thing," says Dick Spear, marketing manager at Independent Technologies. "Today, there is a total electronic environment with switchboards, private branch exchanges [pbxs], and electronic computer-driven systems." Installers and network administrators now have to navigate through this electronic jungle, and to do so they need dmms. For example, dmms are used to change connections and fuses and to check continuity before power is turned on.

Their importance in maintaining smooth network operation is perhaps even secondary to their use as safety devices. According to test-equipment maker Fluke, for example, today`s technicians and engineers need dmms that not only accurately measure and consistently perform under harsh environmental conditions, but that also meet all current safety standards.

Safety first

"Taking current measurements is one of the most hazardous exercises for cabling installers," says DeWinter. "Installers have to shut down the connector, disconnect the live circuit, and then repower the circuit before the current can flow through the meter." To address this situation, Wavetek offers cpm Series Clamp-on Power Meters that measure current without disconnecting the circuit. The clamp head at the top is built into the dmm and picks up the current through the insulation of the wiring.

Another safety concern of installers is transients. As electrical distribution systems and loads become more complex, the possibility of transient overvoltages increases. Motors, capacitors, and power-conversion equipment can generate spikes, and lightning strikes on outdoor transmission lines can cause hazardous high-energy transients. When an installer works on an electrically powered system, transients--an unavoidable hazard-- occur regularly on low-voltage communications circuits and sometimes reach peak values in many thousands of volts. When this occurs, protection depends on the built-in safety margin of a meter. The International Electrotechnical Commission (iec--Geneva) has developed a new safety standard for electrical measurement equipment--iec 1010-1. If a meter meets this new standard, a manufacturer can mark it with a category and voltage rating.

A meter can be listed in iec categories from I to IV, depending on how much safety protection the device offers. Fluke Corp. designed the 80 Series III dmms for iec-1010 Category III 1000V environments. Wavetek is currently unveiling the HD110-B and HD115-B to meet Category III to 1500V. "The new safety standard divides a facility`s power system into four categories, largely based on the available energy," says Larry Williams, dmm product manager for Fluke. An example of a Category II environment is a 120V branch circuit in a cubicle. A Category III environment is a 480V motor lead on a machine tool." All inputs are protected from overvoltage transients to 8 kilovolts. In addition, many meters such as Fluke`s are independently tested by certifying agencies such as Underwriters Laboratories Inc., the Canadian Standards Association, and Technischer Uberwachungs Verein for this iec-1010 rating.

"Using an unrated or Category II-rated instrument in a Category III environment is risky," says Williams. "High-energy transients aren`t limited to lightning strikes. They occur every time a large load is switched on or off." Fluke has also launched an Electrical Safety Program, an educational campaign aimed at raising awareness of industrial electrical hazards and promoting product safety standards.

Fluke`s program is designed to help educate users on how to identify products that meet industry safety standards and that have passed tests of independent testing laboratories. The program also promotes safe work practices for front-line electricians, technicians, and troubleshooters. Fluke`s ongoing program offers educational seminars and videotapes that outline dangers in the workplace and explain how to avoid injury caused by misapplying products in hazardous environments.

Another important function of dmms is measuring local exchange loop current. High and low loop-current conditions are an increasing problem for the communications industry because the electronic customer-premises equipment is more delicate and less forgiving than the old pbx and key equipment.

"Low loop current," says Independent Technologies` Spear, "results in ghost rings, wrong numbers, or messages that the call won`t go through. High loop current causes scorched circuit packs, network disruptions, and memory failures. If you`re `cooking` your modem or fax, you would know because there would be phantom problems. A phantom problem needs to be looked at. It is like taking your temperature to see if you`re ill." A dmm such as Wavetek`s RMS 225A with a minimum/maximum hold feature can monitor lines for low and high current. Accuracy in reading loop current is required of dmms for the technician to repair the trouble or correctly report it to the telephone company.

Independent Technologies` Loop Current Test Set, which includes the itc-3004 test set and itc-4001 attenuator, measures central-office loop current. Using the test set, installers can accurately test for normal circuit operating conditions before connecting terminal equipment to the central office lines. Using the test set, an installer can determine in seconds if the line is conditioned within the 23- to 35-milliampere limits that provide optimum equipment performance. With the attenuator, an installer can reduce potentially damaging loop current to an acceptable level without affecting the voice or data quality of a circuit.

"The benefit of the Loop Current Test Set, which reads only current, is that the meter simplifies readouts so that the least experienced technician can use it more effectively," says Spear. "Today`s technicians are computer- oriented and they want the results fast, without having to change things on the meter and calculate things. This meter provides these services."

New meter features

dmms now offer practical and user-friendly features such as dual numeric displays, temperature testing, recording, and touch-hold modes. The Tektronix dmm 914 and dmm 916 models, for example, have dual numeric displays that let users read two measurements at once. Technicians can measure the amplitude and frequency of current or voltage without switching between signal displays. The temperature-testing feature of these models eliminates the need for separate temperature meters by measuring temperature on both Fahrenheit and Celsius scales. The Tektronix dmm 916 has a peak-hold feature that captures and displays fast transient events, making it possible to detect anomalies that might otherwise go unnoticed.

Fluke`s dmms feature a recording mode that captures the maximum, minimum, and average reading as they monitor signals. While recording, the meter emits an audible tone that indicates that the tester has sensed or stored a new minimum or maximum reading. Users of all of Fluke`s dmm models can select response times--the minimum time that a signal must be present to be recorded--between 100 milliseconds and 1 second. Models 87 and 87/E also offer a 250-microsecond peak minimum/maximum setting that enables installers to capture fast transients and isolate an AC signal`s peak.

The touch-hold mode on Fluke models captures a measurement and then beeps and locks it in place on the digital display for later viewing. This safety feature lets the user focus on the probe`s location rather than on the meter`s reading while making a measurement. The meter automatically updates with each new measurement when it is in the touch-hold mode. When in relative mode, Fluke meters will remember a reading and show the difference between it and any subsequent readings.

Readability

When you are purchasing a dmm, the character and size of backlighting of the meter are important considerations. Larger liquid-crystal display (LCD) presentations are becoming more popular and prevalent. "Large LCDs are more convenient because when you`re crawling through a ceiling you can look down and see the numbers," says Wavetek`s DeWinter. "Poor lighting conditions, such as dim lighting and blackouts, are common. A meter must have quality backlighting for everyday use."

Wavetek`s meters feature Digi-Glo, an electroluminescent panel with bright, blue-green tint backlighting. "Without proper backlighting, installers can`t read their meter," says DeWinter. "Some meters don`t have backlighting but rather have bright spots injected around the edges that make reading difficult."

Fluke designed its meters with a brighter backlight display and 20% larger digits and a wider viewing angle than most other meters to accommodate users needs. Meters that offer a separate on/off switch to conveniently control the backlight display save battery life.

Durability

An installer should also choose a dmm according to the environment in which it will be used and to the level of durability required. "The environment is directly related to the lifespan of the dmm," says DeWinter. "For example, if you work outdoors where you might drop it, then you are going to need a heavy-duty version."

Wavetek designed its HD meter for heavy-duty use in damp and dusty environments, where a sealed, watertight, drop-proof meter is required. "I hear from so many installers that they are still using our heavy-duty product," DeWinter reports. "They boast about the year they bought the meter and how long it has lasted. Keeping durability in mind is important because instead of purchasing a rugged meter, you need to consider purchasing a meter that is guaranteed to work after falling from a ceiling or 10-foot ladder."

Fluke designed the 80 Series III dmms for durability under harsh conditions. These rugged meters handle day-to-day job stresses while providing the sensitivity of accurate instrumentation, according to Fluke. "Durability really has two forms--electrical and mechanical," says Williams. "In addition to the voltage transients and electrical noise, a dmm is exposed to corrosive fluids, high vibration, extreme temperatures, shock loads, and electromagnetic interference."

The Loop Current Test Kit by Independent Technologies measures loop current by performing inline, termination, and tone tests.

The Tektronix dmm 910 Series contains temp-erature testing, dual numeric display, and peak-hold capabilities.

The Wavetek 220 dmm features a Digi-Glo backlight for better visibility in low light and blackout conditions.