Indoor/outdoor cable turns the corner

This versatile fiber-optic cable makes the transition between outside- and inside-plant environments.

Lynn Haber

With local area networks reaching out further into the campus environment, often linking multiple buildings within short spans, the cable market is seeing an increased demand for a fiber-optic cable suitable for use both indoors and outdoors.

In the past two years, a number of cable manufacturers have introduced indoor/outdoor cable to answer the market`s call. Although some vendors entered the indoor/outdoor market earlier, industry participants agree that product acceptance is a more recent phenomenon.

The benefits of indoor/outdoor cable are clear: Installers can run a single cable type and remove a transition point between the outside plant and the inside plant, saving customers time and money.

The National Electrical Code of the National Fire Protection Association (Quincy, MA), nfpa 70-1993, Article 770-50, specifically prohibits traditional outdoor cable from running more than 50 feet inside a building without transition to an approved enclosure. The code was written to protect against the flame-propagation characteristics of outdoor cable. At the enclosure point, indoor-listed cable must be used.

This means the cable installer must make a conversion from one fiber type to another fiber type, which includes prep work on the fiber--stripping the jacket, cleaning off the gel, and stripping off the buffer tubes--the need for a splice tray, the routing of fibers in the tray, and other similar details. On the other side of the tray, the installer works with indoor cable, which is easier to prep, route, and splice. The labor to do the conversion takes about 15 minutes per cable, on average, according to vendors.

Today, well over a dozen competitors offer indoor/outdoor cable. Most offer loose-tube cables for indoor/outdoor use, while several offer tight-buffered cable for similar applications.

The challenge for all manufacturers of this product type is to design a product that meets the most stringent requirements for both outside- and inside-plant applications. With no specific industry standards for indoor/outdoor cable on the books, manufacturers pick and choose among existing specifications for indoor cable and outdoor cable to meet targeted application guidelines.

According to product manufacturers, indoor/outdoor cable should meet the harsh requirements of outdoor applications, i.e., resistance to cold and moisture, and also be fire-retardant and easy to handle for indoor applications.

According to Marvin Ashby, chairman of the communications sector of the Insulated Cable Engineering Association (South Yarmouth, MA), a body that creates standards for cable, a proposal for an indoor/outdoor cable specification will be put on the table by year-end. "It`s time to focus on a specification for indoor/outdoor cable because of the increased use of the product and its maturity in the marketplace," he says.

The eighth edition of bicsi`s (Tampa, FL) Telecommu- nications Distribution Methods Manual, due out by year-end, also includes references to indoor/outdoor cable.

Meanwhile, cable installers and their customers are left to sort through the claims and counterclaims manufacturers make about their respective indoor/outdoor cable products.

Loose-tube configuration

To begin with, indoor/outdoor cable is available in two designs: loose-tube and tight-buffered. Both cable types have been available for many years. However, loose-tube cable has its roots in outside-plant applications, while tight-buffered cable is typically used for indoor applications.

The approach taken by most manufacturers of indoor/ outdoor cable is to refine the design of loose-tube cable to make it suitable for interior use. "We thought it best to begin with a true exterior-rated product, which gives the fiber the best protection outside, and then refine the design to get the necessary riser approvals for inside usage," says Irv Dwyer, vice president of technology at General Photonics llc (Dayville, CT).

Fitel Lucent Technologies (Carrollton, GA) takes the same design approach with its Option1 product, which was introduced about 18 months ago. "Loose-tube cable has been around for more than a decade and it`s well-proven in the industry. Not only is it robust, but there`s no fiber strain during installation, which can potentially be a life-limiting factor," says Eric Anderson, product manager at Fitel Lucent.

Other features that loose-tube cable lends itself to in the Option1 product, according to Anderson, are true outdoor performance--the ability to withstand temperatures of -40oC --and better fiber density, which means that more fibers can be placed in a smaller cable.

When a manufacturer begins with a loose-tube cable design with the intent of making the product suitable for indoor/ outdoor application, the challenge is to make the cable flame-retardant as well as easy to handle.

The basic configuration of loose-tube cable consists of coated fibers placed within a loose tube, which is then injected with a gel filling to stabilize the fibers and keep moisture out, preventing the cables from freezing. In early product designs, manufacturers would then deploy gel flooding in the cable core--the space between the tubes and the cable. Manufacturers still offer products with gel flooding but some offer a gel-less core in which gel flooding is replaced by a water-blocking material.

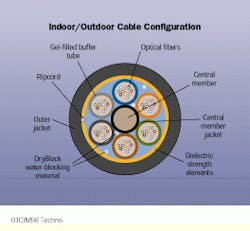

Fitel Lucent uses this approach, for example. According to the company, optical fibers are placed within gel-filled buffer tubes that protect the fibers from crushing, impact, tensile, and environmental forces. The manufacturer then uses a DryBlock core design, which achieves water-blocking performance with the use of super-absorbent polymers instead of flooding compounds. The DryBlock design improves cable entry and handling.

Other manufacturers offer a dry water-blocking option as well. General Photonics, for example, offers both dry-core water-blocking and gel-flooding-type products in its indoor/ outdoor line of cable. The most recent version of RiserLite cable, an indoor/outdoor cable from Mohawk/cdt, a division of Cable Design Technologies (Leominster, MA), includes a water-swellable tape for water-blocking, according to Mike Connaughton, fiber-optic product manager at Mohawk.

Siecor Corp. (Hickory, NC) also uses water-blocking tape in its Freedm indoor/outdoor cables. "The days of indoor/outdoor cable being thought of as messy are gone, thanks to water- soluble tapes and yarns," says Alan Dixon, product specialist, premises cable, at Siecor. Not only do these water-soluble materials eliminate contact with gels, but cable preparation time is cut in half as well, he adds.

Whether the cable designs use gels exclusively or gels and water-soluble materials, protection of the fibers from water is important to the integrity of the fiber and its performance. If a crack develops in the cable jacket, water can creep inside and freeze, potentially splitting the jacket. This, in turn, can result in increased attenuation or a break in the fiber itself.

While inside-plant conditions are considered the more benign of the two environments in an indoor/outdoor application, manufacturers using loose-tube cable must redesign the product, specifically the gel and black polyethylene jacketing materials, in order to pass the Underwriters Laboratories (UL) 910 flame test.

Central- versus multiple-tube design

Buyers of loose-tube cable can also choose between central-tube and multiple loose-tube designs. In a central-tube design, all fibers are positioned in the same cavity. In contrast, fibers in a multiple loose-tube design are bundled in small buffered tubes.

Vendors may offer one or both designs. The consideration for a purchasing decision centers on access to the fiber, according to Dixon. In a central-tube design, all fibers are exposed when the central tube is opened. When accessing fiber in a multiple-tube design, only the tube containing the sought-after fiber needs to be opened.

Manufacturers such as Siecor carry both cable types. "The multiple loose-tube design tends to be more popular, but one advantage to central-tube design is that it tends to have a smaller cable diameter," says Dixon.

When it comes to terminating the indoor/outdoor cable, in a wiring closet for example, some companies offer a breakout kit. Priced at $25 to $30, Mohawk`s kits include 900-micron tubes for each fiber. Crimp tools are used to secure the breakout kit onto the cable. Termination then takes place as usual, according to Connaughton.

Manufacturers may offer several versions of indoor/ outdoor cable in their product lines. Mohawk, for example, in its RiserLite product line, offers a single-jacket loose-tube cable for aerial or conduit installation; an armored cable with steel corrugated tape for direct burial applications; and a zero-halogen jacket for use in applications such as tunnels, where there is great concern about excessive smoke due to burning.

Fitel Lucent`s Anderson says the company is also exploring armored versions of its indoor/outdoor cable product.

Another feature of indoor/outdoor cable is fiber count. Manufacturers in some cases offer cable with a fiber count range from 2 to 288. This year, Siecor added Freedm/lst cable, with a 2- to 12-fiber count, to its existing Freedm cable line, which has fiber counts of 2 to 288 fibers. "We designed the Freedm/lst for low-fiber-count applications," says Dixon. A 3-millimeter tube houses 2 to 12 fibers, for a total cable diameter of 7 mm, or about 1/4 inch.

Tight-buffered cable

Users looking for a tight-buffered indoor/outdoor cable can turn to Optical Cable Corp. (occ--Roanoke, VA) and CommScope Inc. (Claremont, NC). According to Susan Adams, vice president of marketing at occ, the company offers several options for indoor/outdoor cable in its product line, which she says is proven for indoor/outdoor data-communications, video, and audio applications.

The core design of tight-buffered cable has remained stable, says Adams. Distribution-style cable, for example, noted for its smaller size and the capability to have a high fiber count, has one fiber/buffer, acrylate fiber coating, pvc buffer, aramid strength member, and an outer jacket.

The company offers several buffer options: Ultra-Fox Plus, Ultra-Fox, and Easy Strip. Basic cable styles include distribution, breakout, and subgrouping. The company also offers armored cable. The number of fibers in distribution cable can be as high as 144 for riser and 84 for plenum. For breakout cable, the count is as high as 108 for riser and 102 for plenum. Subgroup cable can have 6 or 12 fibers. In this category, 6-fiber subgroups can be bundled in threes, while 12-fiber subgroups can be bundled in fours. "We also have the capability to package fibers in higher numbers--72 to 156," says Adams. Cables can also be purchased with different jacketing, such as zero-halogen, and a stiffer jacket for aerial applications.

Several manufacturers of loose-tube indoor/outdoor cable do not recommend using tight-buffered cable for indoor/outdoor applications. These critics assert that tight-buffered cable provides insufficient protection against moisture; that it is not suitable for temperatures of -40oC; and that the fiber in this cable experiences more strain than in the loose-tube design.

Companies that make both cable types--such as Siecor--used to recommend tight-buffered indoor/outdoor cable in the early 1990s, but stopped recommending it for such use when they introduced a loose-tube indoor/outdoor cable. "We used to say it was okay to use tight-buffered cable indoors and outdoors but now we just recommend it for indoor use," says Dixon.

General Photonics, which also manufactures tight-buffered cable, does not recommend it for indoor/outdoor use.

But according to occ`s Adams, tight-buffered cable has been successfully used for indoor/outdoor applications, and the company`s products undergo laboratory testing to meet various industry specifications. In addition, tight-buffered cable offers better protection, is not messy because there are no gel fillings, is easier to work with, is more flexible, can be pulled around multiple bends or hung vertically, is easy to terminate, and has lower installation costs.

Critics agree that low-fiber-count tight-buffered cable costs less than loose-tube cable, but note that as the fiber count increases, tight-buffered cable becomes more costly.

CommScope, which sells a line of loose-tube indoor/outdoor cable, introduced a tight-buffered indoor/outdoor cable several months ago. The product, called Triathlon, offers the best of both worlds, according to the company: the ruggedness of a loose- tube cable and the ease of installation of a tight-buffered cable.

Benny Blell, fiber-optic product engineering manager at CommScope, says the tight-buffered indoor/outdoor product has shifted to non-PVC super-absorbent polymers in its design. This is because pvc is not suitable for fiber-optic cables subjected to the harsh environmental conditions found in outside-plant applications.

The new product meets or exceeds a number of industry tests, including Bellcore GR-20 and GR-409, according to Blell.

While it might appear that CommScope has two competing product lines, the vendor says the products have two different applications and different fiber counts, and explains there are some limitations on the tight-buffered cable. For example, the tight-buffered cable has a 24-fiber limit, compared to a 144-fiber limit with loose-tube. "We also don`t recommend the tight-buffered cable for distances in excess of 150 meters or for lashing aerially," says Blell. The initial cost for the tight-buffered product is 5% to 10% higher than loose-tube cable, but connectorization is less expensive.

Indoor/outdoor cable must be able to withstand severe tempera-tures, to -40oC, and must be water-repellent. To achieve the latter characteristic, Option1 cable from Fitel Lucent Technologies in-corporates DryBlock, a super-absorbent polymer, around the buffer tubes, rather than using a gel flooding compound.

Loose-tube indoor/ outdoor cable is available in both central-tube and multiple loose-tube designs. Siecor Corp.`s Freedm multiple loose-tube cable (left) can accommodate 2 to 288 fibers.

Both the fibers and buffer tube are color-coded for easy identification. The company`s lanscape central-tube design is shown on the right.

Triathlon tight-buffered cable, recently introduced by CommScope Inc., can withstand harsh outdoor conditions and is easy to install, according to the manufacturer.

Lynn Haber is a freelance writer specializing in networking and telecommunications issues.