Safety rises to the forefront as fiber installations increase

The importance of knowing the ins and outs of safe fiber handling techniques.

Increasingly, enterprise end users are seeking out optical-fiber additions to their networks. And as you engage in increasingly more fiber installation work, you’ll need to be mindful of safety techniques.

It will mean creating an efficient working environment with proper lighting and tools. It will also mean wearing proper eye protection and practicing safe fiber-preparation techniques. Failing to take these steps can be costly in many ways.

While many contractors are already taking safety seriously, Hutch Coburn, a representative for the Fiber Enterprise Product Management Team for the Americas, ADC (www.ADC.com), says there is a lot of room for improvement.

“It (safety) gets due justice, but improvements can be made,” says Coburn.

Larry Johnson, president of The Light Brigade (www.lightbrigade.com), notes that accidents cause health insurance to go up, and can lead to an increase in the amount of days lost from work. And if you suffer a fiber-related accident, recovery can be difficult. Besides the safety issue, production is the key. If a person is injured on the job, they will not be productive.”

There are signs that the industry is taking a new focus on safety issues when working with optical fiber. BICSI (www.bicsi.org), for example, has added an optical-fiber safety class to its list of class offerings. One of the Light Brigade’s training topics on video and CD is Fiber Optic Safety (#W-4LJ). In addition many manufacturers are coming up with safety enhancements on their fiber-related products. Sparked by the popularity of fiber-to-the-home (FTTH) installations, these tools are smaller, faster, less expensive, and feature more safety improvements.

No time like the present

All of these steps are coming at the perfect time. Industry sources report that overall optical-fiber installation and usage are on the increase. At the same time, fiber-related accidents are happening during terminations.

“I think this does happen more often than we know,” says Jim Parker, field technical manager for Kitco Fiber Optics (www.kitkofo.com), which makes kits that contain tools for assembling optical-fiber connections. The kits include ovens, connector holders, crimpers, alcohol bottles and cleavers.

“A lot of the time, there’s no reporting of the incidents because [installers] remove it off of their clothing; or, if they have a finger with glass embedded in it, they remove it themselves or have someone else remove it,” Parker continues.

Meanwhile, there is a lot of optimism when it comes to fiber deployment. Some, like Parker, say many enterprise end users who are planning to upgrade their networks are switching over to optical-fiber products. As new buildings are being built, optical fiber is being considered in the planning stages.

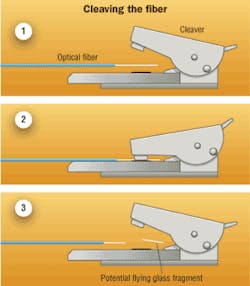

Some cable manufacturers, including Sumitomo Electric Lightwave (www.sumitomoelectric.com), report a marked increase in the use of fiber this year. The company now makes DriTube, a ribbon cable that does not have gel in its central tube. (Gel must be carefully removed with solvents during the installation process.) The gel-free cable is a safety enhancement that limits a worker’s exposure to harsh chemicals. Sumitomo’s new handheld FC7 cleaver, meanwhile, features a safety enhancement catch basin designed to collect broken pieces of fiber.

Sumitomo Electric Lightwave’s growth parallels the 30% industry growth cited in industry market reports. Gary Bishop, director of product management, says the company’s orders are significantly larger than a year ago. He attributes much of the growth to FTTH installations, and to carriers like Verizon (www.verizon.com) who are living up to fiber deployment projections.

“We have witnessed strong market demand for fiber deployment, which has, in turn, stimulated R&D efforts in the development of new products and innovations,” says Bishop. Adds Kitco’s Parker, “It seems that we are coming out of the telecom slump that we were experiencing just a couple of years ago.”

Optical-fiber manufacturers like Corning Cable Systems (www.corningcablesystems.com) report that fiber-to-the-x, FTTH, curb, and node are all driving fiber installations. Corning Cable Systems, like Sumitomo Electric Lightwave, also now makes two gel-free cables: ALTOS and FREEDM.

The company reports that dropping prices for optical fiber are making these installations all the more inviting. Training and installation contractor company Poe Enterprises (www.cabletraining.com), for example, says it is experiencing 10% more optical-fiber installation work than last year. That, in turn, was up some 10% over the previous year.

Safety challenges

While installations are on the increase, Johnson says the actual spans of fiber are getting shorter. While longhaul fiber deployments require few connections or splices, FTTH or fiber-to-the-desk require much shorter spans but more terminations. “We are doing more [fiber] to the desktop lately,” acknowledges Paul Murray, director of operations for the contracting company Bazon-Cox & Associates (www.bazcox.com).

But how well have contractors kept up to speed on fiber installation safety techniques?

“My view is that in the contracting community, there is a very diverse spectrum in terms of skill sets,” says ADC’s Coburn. “Some are a lot more advanced when it comes to using fiber than others. Some don’t understand the ins and outs of fiber.”

As a result, the potential for accidents is greater. Installers working with multimode in the premises will be faced with a lot of connectorization. Those who are installing singlemode will be facing a lot of splicing. In either setting, the fiber must be prepared and cleaned, and when done correctly, workers will properly handle the fiber and safely dispose any fiber chips that are left over from the termination process.

Johnson believes that safety challenges increase when fiber is brought deeper into the enterprise, where termination is conducted at interconnection points. Here, connector terminations are made at each end of the cable, often done on a simple table and under available lighting. By contrast, workers conducting singlemode fiber installations will work in a splicing tent, trailer, van or other setting where they can clean and conduct terminations.

“They [premises installers] normally don’t have a good work surface or good lighting, and the environment around them is not as good,” says Johnson. “The technician working in a splicing van or trailer is better off than the guy in the building, as the environment in the vehicle is controlled, and so the concerns of safety are there.”

During premises termination, the worker conducts stripping, insertion, cleaving and polishing. “It just all adds up to more contact with the optical fibers,” says Johnson, and a greater risk for injury. “I wouldn’t say there are a lot of accidents in terminations, but any fiber technician who works a lot with fiber has had a fiber splinter,” says Johnson. “This is especially true with connectorization in the premises.”

Common sense goes a long way

Basic safety steps when terminating optical fiber often involve common sense. For example, do not eat or drink while working with fiber, as a loose fiber chip can become stuck to nearby food and later be ingested by anyone working in the area.

Even safety eyeglasses can be a problem-if you remove them to rub your eyes without cleaning your hands first.

“The best protection is to be vigilant, organized and methodical about what you are doing,” says Pamela Poe, president of Poe Enterprises.

Other safety basics include:

• When working in a building that has active electronics, make sure the fiber that is being tested is disconnected.

• Wear eye protection to protect from flying debris, and specially coated safety glasses to protect from exposure to light sources such as lasers or light-emitting diodes (LEDs). Class 1 lasers have power levels that are too low to damage eyes, but Class 2 and above will cause damage to optic nerves. So, wear safety glasses with built-in filters to block certain wavelengths of light to prevent eye damage. (Johnson suggests that anyone working with optical-fiber systems should have a copy of the ANSI Z.136.2-1997 laser safety standard, “Safe Use of Optical Fiber Communication Systems Utilizing Laser Diode and LED Sources.”)

• During the testing process, communicate well with one another. “If contractors are testing a cable for optical loss, which could be hundreds of feet in length, communication between the two is critical for coordination and safety,” says Kitco’s Parker.

• Be mindful of what you are inhaling when working with chemicals while stripping and cleaning the cable. Murray says to avoid being in a confined space, even when using degreasers, and work in well-ventilated areas. Before working in confined spaces, check out ANSI standard Z.117.1, “Safety Requirements for Confined Spaces,” which establishes the minimum safety requirements to be followed when entering, exiting and working in confined space operations. “I know that when I first started, if you would sit in a closet all day and work with no ventilation with isopropyl alcohol, citrus cable degreasers, and baby powder, your lungs would hurt from breathing that stuff all day long,” says Murray.

• Allow as much room as possible when conducting fiber termination. This will let you safely manipulate the cable and fiber, prepare it, and connectorize it. If you are forced to conduct termination in a tight space, such as between rows of racks, use a small, fold-up table as a workstation. “You have to set things up where you can control the fibers around the other parts of the equipment,” says Sam Nelson, manager of field engineering for Corning Cable Systems.

• While eye protection from lasers is certainly important, many optical-fiber related accidents involve the use of hand tools. Parker says it’s important to be trained in proper cable preparation, such as how to safely remove a cable jacket and its armoring.

• Safety equipment should include mats, tweezers, swabs to clean fiber, and proper trash receptacles in which to place fiber chips. During termination, since the fiber must be inserted into the connector, it means that during the stripping process, a small portion of the fiber is extended beyond the ferrule. Workers must prepare the cable by removing the buffer coatings. When the fiber is stripped, the glass conductor center is exposed, and that is where potential problems can occur. So, when working with strippers or cleavers, wear safety glasses.

• While stripping fiber, cut away from yourself. This will prevent you from accidentally cutting yourself should the tool slip.

• While stripping the buffer, cut in small increments to avoid breakage, and use an adequate light source.

These things happen

Despite all the precautions, sooner or later, an accident is bound to happen.

“I’ve gotten splinters in me,” says Murray. “When you’ve been doing it for 15 years, it’s going to happen.”

“It’s like when you work around bees,” says Johnson. “Sooner or later, you get stung by them; just as sooner or later, you get pricked by a fiber chip.”

But proper safety techniques will cut down on the number of accidents. And those techniques don’t end when the work is done. It’s also important to be careful how you leave the workspace after the installation is completed. If you lose a fiber chip and leave it onsite, someone else may accidentally find it later. So, empty all fiber chips into a ziplock bag and dispose of it later.

“We have to leave the space as good, if not better, as it was when we came into it,” says Parker. “We can’t leave glass all over the place, or pieces of cabling. It’s just not professional.”

“You have to watch out for other people who may come in contact with debris after the installation,” says Johnson. “Our goal as an industry is for all to be as safe as possible.”

BRIAN MILLIGAN is senior editor for Cabling Installation & Maintenance.