Testing copper cable for noise

Frank J. Derfler, Jr. and Les Freed

Problem

The copper cable link was tested and certified upon installation, but now that construction is completed and the building is occupied, the data-processing equipment connected to the cable consistently has problems. Retesting the link indicates that the problem is not with the cable or connectors: The problem may be that electrical noise is present in the link.

Solution

Measuring electrical noise on a copper cable is a straightforward procedure, but identifying its origin can be frustrating. Many potential noise sources exist in business environments and some or all of them may operate intermittently.

Procedure

1) Disconnect the cable from the data-processing equipment and connect the cable to a cable tester.

2) Take a noise reading. The lower the reading, the less the electrical noise. (The standard unit for noise measurement is millivolts calculated by the root-mean-square method.)

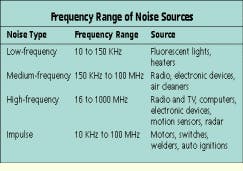

3) If a significant noise level is measured, determine its frequency range, because signals from common electrical sources often occupy specific frequency bands.

4) Using blueprints or other documents, trace the route of the cable run. Walk the route and look for noise sources in the indicated frequency range.

5) Systematically disconnect potential noise sources, retesting the cable after each shutdown. Keep in mind that turning off a device may not deactivate it. Check for built-in batteries or power supplies.

6) If the noise problem is intermittent, it may not always show up on the cable tester. In this case, it may be necessary to attach an impulse noise recorder to the cable.

7) Once the noise source is located, it may be necessary to reroute the cable away from it. If it is impossible to avoid electric motors, elevators, fluorescent lights or whatever is causing the problem, consider pulling shielded twisted-pair cable to replace the installed link.

Frank J. Derfler, Jr. is senior networking editor at PC Magazine. Les Freed is author of the Crosstalk communications program. This tip is adapted from their book, Get a Grip on Network Cabling.