Analog and digital tester manufacturers slug it out over TSB-67

Cable tester accuracy and TSB-67

Jim Bordyn

Datacom Technologies

Editor`s Note: To date, manufacturers of Category 5 local area network cable testers have applied so-called analog technology to the problems they encountered. One manufacturer has recently developed a device based on digital technology to serve the same needs. It is important that buyers and users of these devices understand the differences between the two approaches, because these differences are currently being highlighted in the marketing literature of both camps. Here are two viewpoints on tester technology and the standard governing it, TSB-67. The first is by a manufacturer of analog devices; the second is by a manufacturer of digital testers. An update on the tester standard follows.

Recent discussions in the cabling industry have involved field-tester accuracy and how it is specified in the forthcoming Technical Systems Bulletin-67 of the Telecommunications Industry Association (Arlington, VA). Some background on the development of this new testing standard may shed light on the issues involved and show how it is already impacting the design of cable testers.

The TIA`s link performance task group has spent a year in researching this subject and has evaluated more than 100 technical contributions defining the test instrument characteristics that contribute to measurement accuracy. As a result of this work, the group has decided that field-tester accuracy should no longer be determined, as it has been in the past, by merely comparing measurement results with those of a laboratory network analyzer. Instead, field-tester accuracy should be modeled using a method similar to that which determines the accuracy of network analyzers.

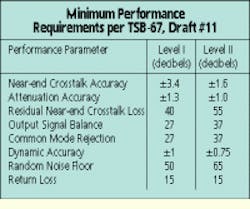

The task group has agreed that the accuracy of field testers in measuring near-end crosstalk should be calculated based on the values of six basic error contributors--residual near-end crosstalk, output signal balance, common mode rejection, random noise floor, dynamic accuracy and return loss--and that two values for each error contributor will be provided. Minimum performance requirements for Level I accuracy are less stringent than the requirements for Level II. Each error contributor for both accuracy levels has been published in the proposed technical systems bulletin (see "Minimum Performance Requirements per TSB-67, Draft #11," below), with well-defined methods for measuring each characteristic using equipment calibrated to industry-accepted standards. In this way, TSB-67 provides a standardized method for determining the accuracy of field testers, and compliance with the standard will require tester manufacturers to specify each basic error contributor.

Error contributors

The most significant error contributors are residual near-end crosstalk and output signal balance. Residual near-end crosstalk is defined as internal crosstalk created by the tester and its connection to the cable under test. Using a modular jack, such as an RJ-45, on the tester has proved to be a major source of residual near-end crosstalk. Mated pairs of Category 5 modular connectors are permitted up to 40 decibels of residual near-end crosstalk, per TIA`s TSB-40. Used as the tester interface, this modular connection can contribute more than 2 dB of near-end crosstalk measurement error. The modular jack connection also impairs output signal balance.

Two test configurations--for the channel and the basic link--have been defined, and performance has been specified in the standard for each. The channel is the entire end-to-end installed link, including patch cords at each end. In this case, the tester must provide a modular jack connection for channel measurements. The basic link includes only the horizontal cabling from the wall outlet or transition point to the first punchdown--typically the portion of the link for which the cable installer is responsible--plus the test cords supplied with the field tester. The defined models include all of the cable up to the plug at each end, but not the plugs. This requires that tester manufacturers account for these end connections in their own characteristics.

Because of the need to connect link patch cords directly to the tester when making channel tests--and therefore requiring connection to a modular jack--the technical systems bulletin defines two different accuracy levels. Accuracy Level I, with a minimum residual near-end crosstalk level of 40 dB, permits use of the modular jack on the tester and therefore can be used for channel tests. The more accurate Level II will only be possible for basic link tests.

Alternate designs for accuracy

Test-instrument manufacturers have proposed a variety of design approaches to reduce measurement error while still supporting both channel and basic link testing. Some test manufacturers have chosen to avoid the modular-jack-contributed measurement error by using a connector with lower near-end crosstalk. The disadvantage of this approach, however, is that it requires a special test cord to connect to the link; one end holds the special tester connection and the other a modular plug. While this precludes replacement of test cords with common Category 5 patch cords, it does allow the tester manufacturer to guarantee the performance of the complete testing system, including instrument and test cords. This avoids the uncertain near-end crosstalk error contribution of off-the-shelf patch cords.

Another design technique uses plug-in instrument modules to interface to the various link-test configurations. With this approach, the tester can be adapted to make either basic link or channel tests, and to offer the maximum possible measurement accuracy for each. A plug-in module with a special test cord terminated in a modular plug connector can be used for basic link tests, potentially with Level II accuracy. Or, a plug-in module with a modular-jack connector can be used for channel tests, although with only Level I-rated measurement accuracy. The plug-in modules contain all the critical cable interface circuitry that determines the tester`s residual near-end crosstalk and output signal balance. This modular approach also allows the cable interface circuitry to be optimized for each test configuration and cable impedance, further reducing measurement error.

Still another tester design, which has been called the digital approach, uses digital signal processing to reduce measurement error in the tester. Use of the word "digital" is somewhat misleading, however, in that all testers employ some analog and some digital circuitry. It might be more appropriate to talk of the stepped-frequency and pulse methods for injecting test frequencies on the link to determine near-end crosstalk.

Using the stepped-frequency (or analog) method, test frequencies are injected into the cable one at a time and the effects of each frequency are measured. Because it is also the method used by network analyzers, it is a well understood technique and has served as the basis for the development of the new test standard.

Using the pulse (or digital) method, test frequencies are also injected into the cable, but the signals are combined into a single pulse. Digital signal processing is then used to convert the link response into near-end crosstalk levels at specific frequencies. Both approaches, however, are subject to the same sources of measurement error, including residual near-end crosstalk and output signal balance.

Although testers utilizing the pulse method tend to be somewhat faster than stepped-frequency testers in completing near-end crosstalk measurements, there are some significant drawbacks to using the pulse method.

Benefits claimed

One of the benefits claimed for the pulse method is the ability to time-gate out the error effects contributed by the modular jack connector. Time-gating works by inserting a delay between the time that the pulse is generated on the transmitting wire pair and the time that the measurement circuitry connected to the receiving wire pair is turned on. This enables the tester to ignore some of the first received near-end crosstalk signal.

Unfortunately, to ignore the modular jack effects in this way, it is also necessary to ignore several inches--perhaps even several feet--of the patch cord. As a result, you will not detect problems resulting from improper termination of the patch cord. And, because the channel is defined to include the entire patch cord up to but not including the end connector, this testing method technically precludes making channel tests, as defined by the technical systems bulletin.

The degree to which the pulse method can time-gate out measurement error effects is also limited. The effects of residual crosstalk, for example, cannot be completely eliminated with time-gating. Some tester-created crosstalk propagates down the link and arrives back at the measurement circuitry at unpredictable times due to varying cable lengths. Also, time-gating cannot eliminate any of the error effects of output signal imbalance. And finally, because it requires a wideband detector to measure all frequencies to 100 megahertz, the pulse method is sensitive to externally generated radio-frequency interference, such as that generated by nearby two-way radios or fluorescent light ballasts.

On the other hand, most testers that use the stepped-frequency method utilize a narrowband detector for measuring crosstalk. Narrowband detectors are tuned to respond to a single frequency at a time, in the way that a radio is tuned to receive only one station. Use of a narrowband detector lets the tester ignore externally generated signals that affect measurements made using a wideband detector. The price you pay for the reliability of the narrowband detector, however, is the settling time needed by the detection circuitry as it tunes to each test frequency.

Choice of a Category 5 cable tester, then, comes down to tradeoffs among a number of characteristics. Among them are testing flexibility, defined as the ability to test both basic link and channel, as well as adaptability to different cable types; measurement reliability, which can be described as near-end crosstalk measurement accuracy and external noise immunity; and tester speed. The latest-model and most capable stepped-frequency testers offer greater testing flexibility and measurement reliability, with only a minor penalty in testing speed. Such small differences in tester speed--40 seconds vs. 20 seconds for a complete autotest, for example--may not be significant to an installer, who may be paced by other tasks, including documentation, labeling and cable dressing during link certification.

Several different testers using a variety of design approaches and proclaiming compliance with the technical systems bulletin will soon be available. These new tester design approaches should be evaluated first in terms of their ability to conform to the new test standard, and then based on other useful features.

Jim Bordyn is marketing manager at Datacom Technologies (Everett, WA), a manufacturer of local area network cable testers.