Installing pre-cabled conduit and duct

Rob Gilberti, Jr., Chromatic Technologies Inc.

Problem

Often, copper and fiber-optic cables must be placed in flexible conduit or duct to conform to regulatory safety codes, meet customer requirements or provide protection from environmental hazards. Placing conduit and then pulling cables can be costly and time-consuming, particularly in complex installations.

Solution

One method to eliminate this two-pull scenario is to install pre-cabled conduit or duct. With this approach, installation time can be cut approximately in half?one pull vs. two pulls,?thereby reducing labor costs.

The inner cables?copper or fiber-optic?experience minimal stress during installation, reducing the possibility of damage from handling. Because cables can be installed in most types of flexible conduit or duct, this approach can be used in direct-burial placement, directional boring, aerial lashing and placement as innerduct (sub-duct) in larger existing ducts. Riser- and plenum-rated cables can be used for indoor placement.

Procedure

1) Determine proper cable length and slack requirements.

2) Survey installation route to determine any unusual obstacles such as severe bends, obstructions or transition areas.

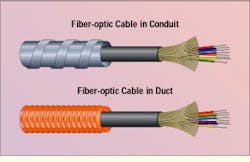

3) Specify and purchase cable pre-installed in either flexible conduit?for example, interlocked armor?or corrugated innerduct.

4) Install cable-in-conduit/duct according to normal installation methods suitable for cable and conduit/duct as indicated by the manufacturer.

Pre-cabled conduit (top) or duct (bottom) can reduce installation time.

Rob Gilberti, Jr., is an application engineer at Chromatic Technologies Inc., Franklin, MA.