Recognizing innovative cabling systems, projects and programs

By Patrick McLaughlin

For the sixth consecutive year, Cabling Installation & Maintenance honors organizations and people who drive the information and communications technology (ICT) industry forward through the Cabling Innovator Awards. The program celebrates products, systems, projects, and programs that and enable better, more-efficient communications for users of information and communications technologies around the world. The program recognizes ingenuity and innovation wherever it is found in the value chain of cabling-system design, installation and administration.

Our judging panel comprises industry professionals with vast experience in the specification, design, installation, evaluation, and administration of ICT systems. That panel evaluated each entry based on six criteria.

- · Innovative approach to product, system, program or project design and implementation

- · Value to the user, which can be measured by qualities including return on investment, loss prevention, or business-efficiency gains

- · Sustainability, characterized by overall eco-friendliness, long-term value, or lifecycle cost-effectiveness

- · Meeting a defined need as a well-conceived and well-executed initiative that fully meets specific user requirements

- · Collaboration, which can include communication and cooperation throughout the value chain through which the entry was developed, produced, procured, or deployed

- · Impact, recognized as the difference that an innovation makes on the professionals involved, on the productivity of its ultimate users, or on society as a whole

Based on our judges’ evaluations, worthy applicants are being recognized as having achieved Silver, Gold, or Platinum status for their innovations.

Silver awards: Marked improvement

A Silver level Cabling Innovator Award is granted to an innovation that has resulted in not just incremental improvement, but in marked improvement over previous methods, approaches, or use of systems and products.

Here are the 2020 Cabling Innovators Silver Award honorees.

CommScope’s M-LOC Cluster Connector System installs with a single push/lock motion that reduces installation time by more than 75% and uses a keyed feature that ensures accuracy in port mating—saving installation time, cost, and worries. The M-LOC jumper uses a metal/polymer construction for durability that additionally reduces site rental fees with a lighter-weight design. The M-LOC cluster jumper family supports connectivity to 4 or 5 antenna ports with a single latching connection, while offering excellent performance for both time division duplex (TDD) and future frequency division duplex (FDD) cluster connector systems.

The PSI-15 protection sleeve insertion tool from Jonard Tools is designed to make loading protection sleeves onto fiber a quick and easy process. Inserting fiber into a protection sleeve is a precision process. The 250-µm fiber must fit into a sleeve opening that is between 1 and 2 mm. Aligning the fiber to the sleeve can be tedious. The PSI-15 can store 15 protection sleeves. Its conical fiber-feed surface guides fiber directly to the protection sleeve, and the tool facilitates fiber loading by providing a guide for the fiber to load directly into the protection sleeve. When one sleeve is loaded and removed from the tool, another sleeve falls into place.

The Miller MB-07 Cable Slitter from Ripley Tools is designed specifically for Corning’s RocketRibbon Extreme Density Cable, which has a fiber count of 1728. “Corning required a reliable tool to access fiber in midspan applications with higher repeatability than using a field knife, which has the potential to damage cable and fiber,” Ripley explains. The MB07-7000 midspan access tool has been certified by Corning for use with the RocketRibbon 1728. The slitter is constructed with an aluminum body; it enables end or midspan cable preparation to access subunits and ripcords without damaging the fiber. The design includes a safety shielded factory-set tool steel blade with a unique finger “comfort grip” and brass guide wheel to reduce drag while performing longitudinal cuts.

Gold awards: Excellent innovations

Gold-level awards are earned by organizations whose innovations are judged to be excellent, and whose benefits are clear. Each gold-level innovation makes a substantial improvement over previous methods employed, approaches taken, or products and systems used.

Following are 2020 Cabling Innovators Gold Award recipients.

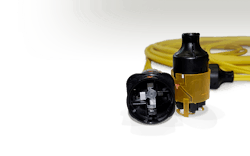

PowerShift 2000FA is the latest addition to CommScope’s PowerShift family of intelligent plug-and-play DC power supplies. In cellular networks, PowerShift regulates the voltage at the remote radio unit (RRU), keeping it at a constant -54 VDC on a steady basis without a tower-top converter. “Cell sites are steadily demanding more and more power at the top of the tower,” CommScope explains. “New radios, as well as those in development, need more energy to help meet the world’s insatiable thirst for more capacity and faster throughput. These radios, whether in an LTE network or a new 5G network with massive MIMO architecture, have raised the average wattage requirements per RRU from 100 to 300 watts at the turn of the century to 1 to 2 kilowatts today. Moreover, operators are installing more RRUs at the tower top than ever before.” Typically, thicker and heavier copper cables would be used to deliver power to these new RRUs. “What the industry needed was a way to keep using the same copper cables that were on a cell site, even as the radio’s power requirements increased,” CommScope further explained. “This would enable a simpler, less-expensive upgrade. It also would allow a company to standardize its cabling, deploying the same diameter cables across all sites, effectively lowering inventory costs.” The PowerShift 2000FA can supply up to 2000W per RRU in a one-rack chassis, supporting up to 4 RRUs per rack, with both ganged and front inputs to make connections easy in tight spaces. It also increases battery backup times by as much as 50%.

The HD Fusion Fiber Wall Mount Splice Enclosure from Panduit houses, organizes, manages and protects cable-to-cable fusion splice connections. It accommodates large-count fiber-optic cables typically coming in from outside the building, transitioning to smaller-count cables within the data center. This enclosure features splice trays that can accommodate individual or ribbon fiber and comes in two different sizes to splice up to 3456 fibers or 6912 fibers. The enclosure’s versatility makes it an ideal choice for a variety of applications including building entrance facilities/meet-me rooms, data centers, hyperscale, colocation, and telecommunications. Among the wall-mount enclosure’s benefits for users is the ability to pay-as-you-grow. Multiple enclosures can be ganged together either horizontally or vertically, so enclosures are added only when necessary. The tray can rotate, so it can be easily viewed even when fully populated. The door can be removed and installed without tools, and includes an integrated work surface that can store on the door when not in use.

The HD Flex Raised Floor Enclosure saves real estate by providing space below the raised floor to mount TIA 19-inch rack-mountable patch panels, thereby relieving congestion in racks and cabinets for installing network equipment. Panduit says the enclosure is an ideal data center and colocation solution as a consolidation point or zone distribution area (ZDA). For mainframes or storage area network applications, a ZDA can also save floor space by locating a termination point in a raised floor enclosure rather than in an adjacent cabinet. The raised floor enclosure is capable of accommodating field terminated or preterminated copper or fiber cassettes as a ZDA for rapid data center deployments and reconfigurations. The enclosure provides an efficient and cost-effective method to design and deploy structured cabling systems for open office architectures in any raised floor application.

Panduit’s PatchRunner 2 Cable Manager family was completed with the addition of the PatchRunner 2 Horizontal Cable Managers, which complement the PatchRunner 2 Vertical Cable Managers to deliver an optimized cable management experience. The product family provides value to users on several fronts, all of which impact the bottom line. For example, managers and doors are orderable as a single part number, and arrive preassembled, with the doors attached. This means fewer components to order, inventory and install, resulting in cost savings, and less packaging waste. The managers are robust and sturdy yet lightweight and easy to handle, so one person can install them with ease. Even vertical managers quickly attach with a couple bolts by a single installer. Added space within the managers and between fingers makes it easier and faster for technicians to complete moves, adds, and changes, thereby lowering labor costs. A significant value comes in optimizing space within the telecommunications room. The Enhanced Vertical Manager includes the ability to mount standard 19-inch accessories—including patch panels—within the cable manager, freeing up valuable rack real estate for other equipment.

Senko’s IP-9 connector series’ compact footprint helps make enclosure and terminal sizes smaller, the company says. “With the IP-9, you can double the port density in the same footprint without compromising performance. While the size is small, it still provides an IP-68 water and dust protection rating and mechanically withstands 50 pounds of pull force.” All Senko’s IP-9 connectors are equipped with the company’s safe lock feature, which prevents accidental disconnects. The IP-9 series is available for SC, SN, and MT configurations. “This enables IP-9 connectors to support multiple deployment scenarios with one footprint, such as single fiber SC for FTTH drop, dual fiber connection SN for wireless networks, or multifiber MT for drop terminal applications,” the company adds. “Wireline and wireless network convergence is a key trend in the market, and IP-9 is the most suitable connector for the job.”

LiveLight is the newest feature of Softing’s NetXpert XG. It is a trend plot of the dB loss across a fiber from tester to tester. “That’s dB loss from an SFP at one end of the fiber to the SFP on the other end of the cable,” Softing explains. “You will see the dB loss vs. time on a trend plot on the NetXpert XG in real time. As conditions change, such as effects due to moving a bad connector, you will see loss levels change on a real-time trend chart display.” When describing the common real-world scenarios that gave rise to LiveLight’s development, Softing says, “What if you are testing fiber, and you get an unacceptable loss measurement? Then you retake the measurement, and this time, magically, the reading is good. This is frustrating. Is it the test cables? Did I do something wrong? Could it be an intermittent problem? What if I need to test cables that move as machines move?” Instead of taking a single snapshot, LiveLight offers a continuous light-loss measurement and enables users to view the results continuously on a live streaming plot.

Platinum awards: Breaking new ground

Our final set of awards, the Platinums, have been judged to be superb innovations, characterized by a groundbreaking approach to meeting a need, or establishing a new level of performance, efficiency, ease-of-use, and other beneficial qualities. Here are our 2020 Cabling Innovators Platinum Award honorees.

Belden’s Hirschmann Suzhou plant has been certified by Verband der Elektrotechnik (VDE)’s Test Data Acceptance Program (TDAP), and the MachFlex Super 350 cables have been registered by VDE., “This certification helps Belden and our customers to explore the Industrial Internet of Things world, which is aiming for user-friendly, energy-efficient, instant communication,” Belden says. “Our products and services synergize these requirements. Certified by one of the world’s most stringent laboratories, the Belden Hirschmann Suzhou plant, along with the MachFlex Super 350 Cable family, are ready to serve and connect the world with safety.” The company further adds that it is the first in the world to successfully test automation control cables in compliance to EN 50525-2-11:2011 (Flexible cables with thermoplastic PVC insulation), EN 50525-2-51:2011 (Oil-resistant control cables with thermoplastic PVC insulation), and VDE-PB-0022:2018-07 (Flexible cables for the industry), and granted VDE registration for MachFlex Super 350 product family and TDAP for the R&D testing laboratory under the same standard scopes. “With this certification, Belden can now research and test the entire listed requirements within our own laboratory and submit the data for VDE review and approval,” Belden adds. “The certified test equipment as part of this program includes drag chain testers, torsion testers, bending testers, flame testing machine, tensile elongation tester, micrometers, oscilloscope, oil bath tester, DCR bridge and more.”

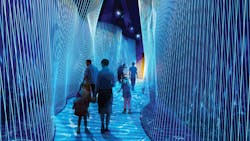

The $54-billion improvement and expansion project for Seattle’s light-rail infrastructure, called the Northgate Extension, was primarily a tunnel section that will accommodate an estimated daily ridership of 41,000 to 49,000 by 2022. For the project, public safety and seamless communication with the rest of the systems were priorities. The project needed an innovative product that would work well in the confined spaces and tunnels, and would seamlessly connect with outside plant, using standard couplers, tools, and installation techniques. The Northgate Extension project used more than 22,500 feet of Dura-Line’s 1-inch Low Smoke Zero Halogen conduit, which was reformulated and launched in 2018. The product offering’s low coefficient of friction provides less stress on the fiber cable, allowing for greater air-jetting installation distances. The installation crews, which worked between the hours of 1:30 and 3:30am for several days in order to complete the conduit installation, pulled the conduit in vault to vault. The 1-inch LSZH conduit were inserted into a larger 4-inch duct, which was encased in concrete and ran the entire length of the Northgate Extension, over 22,500 feet. The crew was able to air-jet fiber cable for the entire length from the safety of their access points. Air-jetting allowed the fiber cable to be inserted at 200 feet per minute. Future upgrades and changes can be made just as easily, from the safe access points, and avoiding disrupting the light rail schedule.

The Ethernet Alliance’s Gen 2 PoE Certification Program enables power sourcing equipment (PSE) and powered device (PD) manufacturers to deliver the functionality end users expect, while helping to reduce the time needed to get interoperable PoE-related equipment to market—something that is in the best interest of both the Ethernet ecosystem and customers alike. “PoE has made great strides recently and its advantages are well-documented,” the Ethernet Alliance says. “As PoE proliferates, so have the range of PoE-capable devices using different brand names and terminology with no visible way to distinguish between standardized and non-standardized solutions. As a result, interoperability issues and market confusion have increased. The EA Gen 2 PoE Certification Program features an exhaustive test regimen built around IEEE 802.3bt PSE and PD equipment that pass these tests can be identified by the appropriate “EA Certified” logo that not only shows compliance but also indicates the power level sourced or required by the device. This allows customers to easily identify compliant PoE devices and their power capabilities/requirements.”

PATCHBOX’s Setup.exe is a rack-component installation support that provides a competitive advantages, increased well-being, safer working environment, and equal opportunities in the information technology sector, PATCHBOX points out. “Using the physical stability of an equilateral triangle the Setup.exe is mounted effortlessly to any 19-inch network rack, forming a secure triangular support,” PATCHBOX further explains. “In seconds, the Setup.exe is secured facing either inside or out of a rack, creating a sturdy and robust support to carry the weight of both rack equipment and laptops, or diagnostic tools, for instance.” When mounted facing into a rack, the Setup.exe securely takes the weight of equipment up to 15 kilograms [30 pounds], for example, switches. During the task of component/hardware installation, the Setup.exe provides technicians the benefit of maintained control of the component, allowing the hands to remain free to complete the task with greater ease and comfort. When mounted facing out of a rack, the Setup.exe creates an ideal workspace for laptops and diagnostic tools, such as when terminating a patch panel. Setup.exe includes a rubberized surface and tool slots.

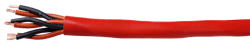

Radix Wire & Cable collaborated with Champion Fiberglass to develop the first-ever Two Hour Fire Rated 300V CIC (cable in conduit) system approved for installation in phenolic conduit. DuraLife II Two Hour Fire Rated CI/CIC Cable in Phenolic Conduit meets the need for a corrosion-resistant, zero-smoke/zero-halogen conduit option for mechanical protection of two-hour fire-rated 300V fire alarm systems used in emergency circuits for transit applications and other damp locations such as underground facilities. “The Radix engineering team led the way in this product’s development, with their extensive knowledge of high-temperature silicone compounds and previous experience with developing cables to meet the extreme environments of the UL2196 two-hour fire-rated test,” Radix explains. “Internal testing began at the company lab, in order to determine optimum cable fill ratios and narrow down the best conduit options. Preliminary testing results revealed a frontrunner, with Champion’s Flame Shield XW Phenolic, and the two companies proceeded to the full-scale fire rating testing at the UL facility in Northbrook, IL. The cable system, including all components, was subjected to the extreme rigors of the UL2196 test, which includes both horizontal and vertical orientation.” The product gives contractors an attractive option to protect critical circuits in transit and underground applications.

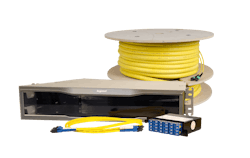

Tripp Lite’s NRFP Robotic Fiber Panel System provides “simple, effective fiber network management through automation,” the company says. “To help data centers add, move and change fiber connections with agility, Tripp Lite offers new Robotic Fiber Panel Systems. These rack-mounted crossconnects make physical fiber connections using robotic latching and remote management. They offer IT professionals unprecedented opportunities to manage their Layer 1 connections on reliable and efficient schedules, with less of the time and expense of strictly hands-on management.” The Robotic Fiber Panel Systems are available in singlemode LC or multimode LC fiber configurations. Each version comes in 2 sizes: a 512-port option and a 204-port mini option. By interconnecting multiple units, users can scale up to a total of 500,000 ports. The units can be configured for all optical signals and all network protocols, Tripp Lite adds. “Using a specially designed mechanical latch, Robotic Fiber Panel Systems typically reconfigure a connection in 20 seconds, as opposed to the hours or days it might take for network engineering to arrive on-site,” Tripp Lite explains. “RFPSs include custom software that controls a 1U logical control unit, installed above the main chassis. They give IT professionals the flexibility to plan network management tasks based on business demands, rather than what fits on-site engineering schedules.”

Patrick McLaughlin is our chief editor.

About the Author

Patrick McLaughlin

Chief Editor

Patrick McLaughlin, chief editor of Cabling Installation & Maintenance, has covered the cabling industry for more than 20 years. He has authored hundreds of articles on technical and business topics related to the specification, design, installation, and management of information communications technology systems. McLaughlin has presented at live in-person and online events, and he has spearheaded cablinginstall.com's webcast seminar programs for 15 years.