Trend-Setting Projects, Products, Platforms Recognized as Award Recipients

Cabling Installation & Maintenance is pleased to present detailed information about the honorees in our 2025 Cabling Innovators Awards program. As it has done since its inception, the program aims to recognize the organization and the people who drive the cabling and information and communications technology (ICT) industry forward. It awards ingenuity and innovation wherever it is found in the value chain of cabling-system specification, design, installation, and administration.

Our judging panel evaluated each entry based on the following six criteria.

- Innovative approach to product, system, program, or project design and implementation

- Value to the user, which can be measured by qualities including return on investment, loss prevention, or business-efficiency gains

- Sustainability, characterized by overall eco-friendliness, long-term value, or lifecycle cost-effectiveness

- Meeting a defined need as a well-conceived and well-executed initiative that fully meets specific user requirements

- Collaboration, which can include communication and cooperation throughout the value chain through which the entry was developed, produced, procured, or deployed

- Impact, recognized as the difference an innovation makes on the professionals involved, on the productivity of its ultimate users, or on society as a whole

Based on judges’ evaluations, worthy applicants are recognized as having achieved Silver, Gold, or Platinum status for their innovations. Recipients of silver-level honors have shown marked improvement over previous approaches, or use of systems and products. Gold-level awards are earned by organizations whose innovations are judged to be excellent, and whose benefits are clear. Each gold-level innovation makes a substantial improvement over previous methods employed, approaches taken, or products and systems used. Platinum awards have been judged to be superb innovations, characterized by a groundbreaking approach to meeting a need, or establishing a new level of performance, efficiency, ease-of-use, and other beneficial qualities.

Here we list this year’s Cabling Innovators Awards recipients by award level, and the remainder of this article will detail each organization’s award-worthy offerings.

Platinum Awards

- CommScope: Propel XFrame

- The Dow Chemical Company: REVOLOOP 3215 BK Recycled Plastics Resin Cable Jacket Copmpound

- EXFO: PXM/LXM Pro Duplex and Multi-Fiber OLTS

- Let’s Talk Cabling: Podcast for ICT Professionals

- Leviton Network Solutions: FDT Category 6A F/UTP Cable

- Panduit: EL2P Power Distribution Unit

- Siemon: Application case-studies in which Siemon’s technology was implemented at two healthcare facilities: Nicklaus Children's Hospital and the University of North Carolina (UNC) Health

- Sticklers Fiber Optic Cleaners: Sticklers Pro360 Touchless Cleaner

- STL – Sterlite Technologies Ltd.: STL Multi-Core Fiber

- Trend Networks: SignalTEK QT Cloud Connected Cable Qualification Series

Gold Awards

- AEM Precision Cable Test: Power over Ethernet PassThru Test Adapter

- Brady Corporation: The i7500 Label Printer

- Clearfield Inc.: 3D Interactive Installation Guides Powered by BILT

- CommScope: FiberREACH Powered Fiber Solutions

- Eaton: Tripp Lite Series Managed Ethernet Switches

- EXFO: FTB Lite OTDR Series

- Fluke Networks: LinkIQ Duo Cable+Network+WiFi Tester

- IFP Connect: Fiber PoE Transceiver

- Leviton Network Solutions: Half-RU Universal 24-Port Patch Panel

- Panduit: Application case studies in which Panduit’s technologies were implemented at the Rockford Public School system and Miller Electric Company

- Patton Electronics: CopperLink CL-SFP Ethernet Extender

- Siemon: Two separate product innovations—bundled fiber trunks for network deployments and high-density 800G cable assemblies for data centers

- STL Sterlite Technologies Ltd.: STL Aerial Fiber Distribution Hub

- Wirewerks: Fiber Deployment Panel System

Silver Award

- Eaton: Tripp Lite Series Media and Mode Converters

AEM Precision Cable Test

AEM’s Power over Ethernet PassThru Test Adapter is designed to extend the diagnostic test capabilities of the company’s TestPro CV100 and Network Service Assistant by enabling in-line testing of Ethernet and PoE connections, while keeping the end device powered and operational. This approach supports troubleshooting scenarios that require uninterrupted service from devices such as PoE cameras, access points, and control systems. A primary benefit of the PassThru adapter is its ability to record power fluctuations and timestamp anomalies over long durations. These logs provide granular insight into transient faults, allowing users to pinpoint the moment an issue occurred and investigate correlations with other network or environmental events. The resulting data can be retrieved using AEM’s TestDataPro software for detailed evaluation. This capability supports better fault isolation and efficient root cause analysis, particularly for intermittent failures that are otherwise difficult to replicate.

The adapter’s logging and monitoring features significantly reduce time-to-resolution for complex failure modes, equipping users with high-fidelity data for decision-making. In environments where service continuity is essential, this tool allows teams to operate with confidence, using evidence-based diagnostics rather than trial-and-error methods.

Brady Corporation

The i7500 Label Printer is designed to meet the rigorous and dynamic demands of manufacturing, logistics, and product ID., Its design epitomizes efficiency and adaptability, Brady points out, noting the LabelSense technology that allows the printer, associated materials, and Brady software to communication bidirectionally, automating and eliminating adjustments and label-wasting tasks. For the user, that means there is no need to manually set print speed, heat, offsets, sensor mode, or sensor location. The i7500 performs those functions automatically without trial-and-error print tests.

Brady describers the i7500 as “high precision, not high maintenance,” pointing out that the printer reduces downtime and maintenance costs, while its intuitive technology translates to increased productivity and throughput.

Clearfield Inc.

Clearfield’s 3D Interactive Field Guides, powered by the BILT app, offer a smarter, more-practical way to train and support broadband field technicians. These guides meet head-on the challenge to ramp up crews quickly while maintaining quality standards; they do so by delivering detailed, step-by-step guidance through a mobile platform that is designed for real-world conditions.

Instead of flipping through paper manuals or static PDFs, technicians can use their phones or tablets to access dynamic 3D product walkthroughs. They can rotate, zoom, and explore each step visually. Accessibility is a significant advantage, Clearfield says. The guides are available offline once downloaded, so technicians on site anywhere—specifically including in rural areas or low-connectivity zones—are not left guessing. Cost savings are realized in several areas: less time spent in traditional training, fewer installation errors, faster job completion, and reduced support calls. Service providers that have adopted the guides report to Clearfield that their technicians get up to speed faster.

Scalability is another asset. The guides cover Clearfield’s most widely used products, from the central office to the customer premises. Updates are pushed directly through the app, so teams always have access to the latest instructions without reprints or retraining. Clearfield strongly states these guides are helping lower the barrier to entry for new workers, creating more-consistent installation practices, and giving providers confidence the job is done right the first time.

CommScope

Propel XFrame. The Propel XFrame solution, part of CommScope’s Propel portfolio of data center solutions, is a floor-mounted fiber frame designed to support and evolve with the demands of data centers and high-performance computing facilities. The low-profile solution can be placed against a wall, back-to-back, or as a freestanding frame for maximum deployment agility. It enables faster, more-flexible deployment and management of high-density optical fiber frames while optimizing data center space an internal resources.

The company points out 6 ways Propel XFrame enhances fiber deployment: 1) expanding options (the standard 19-inch frame supports multiple standardized connector types, including duplex LC/SN and MPO8, MPO12, MPO16); 2) reducing labor costs (it does not require detailed knowledge and experience to deploy and manage, and it provides front access to all panels); 3) optimizing data center space (its low profile and multiple deployment configurations enable users to deploy Propel XFrame in whatever configuration best uses available space); 4) improving density management (it offers 3U-, 4U- and 5U-panel options that accommodate up to 1920 LC duplex, 3072 SN duplex, or 1920 MPO connectors while also accepting simplified, high-density Propel modules and cassettes and standardized connectors); 5) simplifying ordering (it requires a minimum number of SKUs, helping reduce ordering errors and inventory costs); and 6) global availability (available where and when needed, Propel XFrame allows data center operators to accelerate turnup of new facilities or quickly upgrade existing fiber connectivity).

FiberREACH Powered Fiber Solution. CommScope’s FiberREACH Powered Fiber Solution comprises central power supply equipment, a hybrid cable system that incorporates both fiber for data and copper conductors to supply power, and a selection of Ethernet PoE extenders that can connect networking devices. Power is provided via the hybrid cable, which reduces overall design complexity and also reduces the need for new power circuits. All together, FiberREACH offers a high-performance power and data system for critical networking systems.

FiberREACH cabling combines multimode or singlemode fiber and low-voltage copper conductors in one hybrid cable. This enables the connection of a large number of powered remote devices without the need for new conduit, bulky extra cable runs, or the expensive of electrician labor. FiberREACH is a connectivity and enabling technology allowing networks to gain access to a vast and growing ecosystem of applications and low-voltage DC-powered devices, including:

·PoE distance extension

·Optical LAN

·Emergency phones

·HD security cameras

·Digital signage

·WiFi access points

·Small cells

CommScope has merged flexible copper conductors with high-performance bend-tolerant fiber to make cabling pliable and effortless to pull. While combining two cables into one, the powered system easily fits in standard conduit.

The Dow Chemical Company

REVOLOOP 3215 BK Recycled Plastics Resin Compound for Cable Jackets is The Dow Chemical Company’s first single-pellet high-performance linear low-density (LLDPE) compound made with 30% post-consumer recycled (PCR) content, specifically engineered for durable cable jacketing applications. It transforms variable PCR waste streams into a consistent, high-performance compound that meets or exceeds industry standards. Its single-pellet design simplifies processing and inventory management, offering a one-stop solution for cable manufacturers and enables circularity in a traditionally linear industry.

The compound was developed in response to a clear market demand for sustainable materials in the power, telecommunications, and renewable energy sectors. These industries require cable jacketing that is not only durable and compliant with stringent standards, but also aligned with environmental goals. REVOLOOP 3215 BK meets these needs by offering a sustainable alternative that performs on par with virgin materials, enabling cable manufacturers to meet recycled-content mandates and reduce their carbon footprint.

Its development was a cross-functional effort involving Dow’s research-and-development, manufacturing, sustainability, and commercial teams, as well as close collaboration with Dow’s customers. The integrated approach ensured the product was not only technically sound, but also commercially viable and aligned with user requirements.

Eaton

Managed Ethernet Switches. The Tripp Lite Series Managed Ethernet Switches offer a practical and forward-thinking solution designed for the evolving demands of enterprise networks, edge computing environments, and white space installations. The switches combine robust performance, management, and scalability to enable fast deployment and reliable uptime in environments where remote access is critical. Equipped with a built-in web interface with Layer 2 and Layer 3 management software, the Eaton Tripp Lite Series Managed Ethernet Switches enable configuration, monitoring and controlling of network traffic from anywhere. Supporting Gigabit Ethernet with autonegotiation and auto-MDI/MDIX detection, the switches streamline installation by eliminating the need for crossover cables or specialized port configurations. Dedicated SFP uplink ports enable long-distance fiber-optic connections, which is essential for extending high-peformance networking across large campuses or between distributed facilities.

Select models support PoE+, simplifying installation for IP phones, wireless access points, and surveillance systems by minimizing the need for separate power supplies. Its Power Device Monitoring (PDM) can detect and automatically restart offline devices to reduce onsite support and improve system resilience. With a durable metal chassis and standard 1U rackmount design, the switches fit easily into existing infrastructure.

Media and Mode Converters. The Eaton Tripp Lite Series Media and Mode Converters offer a flexible solution for modern network infrastructures. By enabling seamless conversion between copper and fiber, as well as between multimode and singlemode fiber types, the converters enable organizations to upgrade networks and support longer transmission distances without the expense of replacing existing cabling. Copper-to-fiber media converters allow signals to exceed the 100-meter limitation of conventional copper cable.

Designed for use in 100-Mbit/sec Fast Ethernet, 1000-Mbit/sec Gigabit Ethernet, and 10-Gbit Ethernet networks, these converters support long-distance data transmission up to 50 miles, enabling connectivity across campuses, industrial sites and facilities. Equipped with MDI/MDIX crossover detection, the converters automatically detect and choose the connection required, eliminating the need for crossover cables. The media and mode converters support a wide range of port types, available for SC, ST, and SFP port configurations. SFP models have an open SFP port that allows users to install their own transceiver.

EXFO

PXM/LXM Pro Duplex and Multi-Fiber OLTS. EXFO’s PXM/LXM Pro Duplex and Multi-Fiber OLTS is a complete, cloud-connected certification solution built to transform Tier 1 testing in high-density data center and enterprise environments. Designed for speed, accuracy, and ease of use, the PXM/LXM Pro removes traditional bottlenecks from both duplex and multi-fiber testing, enabling faster project delivery, greater consistency, and full standards compliance.

It certifies duplex and multi-fiber links for loss, length, and polarity at two wavelengths in one second, helping technicians closeout jobs faster. Its patented Click-Out adapters allow for seamless switching between connector types, including MDC, SN, LC, MPO, and Systimax MTP, without recalibration. Combined with EXFO’s one-cord reference method, it eliminates the hassle of managing pinned/unpinned configurations, ensuring full compliance with TIA, ISO, and IEC standards while avoiding test errors.

The PXM/LXM Pro is fully integrated with EXFO Exchange, EXFO’s cloud-based test and measurement platform. Test jobs can be pushed to the field directly from the office and executed even in offline red zones, with results syncing back automatically when connectivity is restored. Centralized data management, real-time visibility, and automated result uploads keep projects on track and audit-ready. With every test result tied to a specific job and technician, project managers can eliminate paperwork, enforce standards, and accelerate delivery without sacrificing quality or control.

The PXM/LXM Pro is capable of detecting duplex and MPO polarity errors in trunk cabling before the network goes live, providing graphical polarity maps and first-time-right testing, eliminating blind spots that previously were undetectable with traditional tools. The tester is equipped with a large hybrid contactless connector that supports both APC and UPC connectors, making it versatile for singlemode and multimode networks. Its large-core detector ensures precision measurements with minimal uncertainty, which is critical in high-density, high-performance environments. Each unit features a smartphone-grade capacitive touchscreen that is responsive and visible from any angle, including in dark or sunlit areas. Results can be directly exported to FastReporter, EXFO’s test data processing and certification software, to generate reports.

FTB Lite OTDR Series. The FTB Lite OTDR Series redefines how fiber-optic testing is done in today’s high-pressure, high-scale deployment environments, EXFO says. It is built on the FTB platform and tightly integrated with EXFO Exchange, and was purposefully engineered to eliminate real-world roadblocks and empower teams to deliver fiber deployments faster, with fewer errors and at lower costs.

At the heart of the series is a shift from standalone test instruments to fully connected field platforms. With always-on cellular connectivity, test results are automatically uploaded to the cloud, eliminating the risks of lost data, manual errors, and compliance issues. The direct link to EXFO Exchange transforms FTB Lite OTDRs into smart nodes in a synchronized test ecosystem, bridging the gap between field execution and project oversight.

Another innovation is the FTB Lite Series’ focus on usability. Field testing is no longer the domain of highly experienced experts, because every device in the series features an intuitive, smartphone-inspired interface. An embedded optical link mapper (OLM) comes standard, allowing even junior technicians to confidently identify fiber faults and validate installations. Its design flattens the learning curve, reduces training time, and enables faster ramp-up for new hires.

The series’ impact is measurable in the form of fast job closeouts, fewer repeat site visits, improves SLA compliance, and significant reductions in post-deployment troubleshooting. By automating result capture, synchronization, and reporting, the platform minimizes human error and administrative burden, thereby improving return on investment and ensuring first-time-right deployments.

Fluke Networks

Fluke Networks LinkIQ™ Duo Cable+WiFi+Network Tester combines the company’s trusted cable and network testing solution with WiFi and network testing in the first tester to combine Fluke’s expertise in cabling qualification with network and WiFi testing.

Each link of the connection between the WiFi user and the network must perform properly for maximum performance. The LinkIQ Duo allows technicians to validate each. First, the LinkIQ can qualify the performance of the cabling between the network and the access point up to 10 Gbits/sec, which is critical to the performance of today’s high-speed WiFi networks. Second, the connectivity to the switch can be validated along with the maximum data rates of the switch port. Third, since most WiFi access points use Power over Ethernet, the LinkIQ can determine if sufficient power is available for the task. Fourth, connectivity to key assets such as a WiFi controller can be verified. Fifth, once the access point is operational, the LinkIQ can check the configuration of the access point as well as the wireless environment in which it is operating.

These capabilities are indispensable both when installing and troubleshooting wireless networks. Instead of wasting time swapping and using multiple incomplete, clumsy, or complex tools, LinkIQ Duo includes all the features necessary for troubleshooting WiFi connection and performance issues and identifying the location, availability, and configuration of access points—all in a lightweight, handheld package.

The LinkIQ Duo makes it straightforward to understand the causes of common WiFi problems including:

·Can I connect to Wi-Fi?

·What is affecting my Wi-Fi performance?

·Where is the access point? (Sometimes they are not easy to physically locate!)

·How is the Access Point configured?

·How do I test Wi-Fi 6E / 6 GHz?

The gesture-based, high resolution touch screen offers one-touch measurements that deliver easy to interpret results, such as a cable performance “speedometer” and a unique visualization of channel usage, overlap and access points for a clear understanding of the existing WiFi environment. Clear, uncluttered displays make it easy for experts and novices to understand the results. Results for the cabling, network, and Wi-Fi can be stored using LinkWare, the industry’s de-facto reporting standard.

IFP Connect

IFP Connect offers what it describes as an industry-first full gigabit PoE+ (30w) transceiver that allows PoE and data to be sent up to 330m/1000’, leveraging just one strand of fiber and 18/2 copper cable. The PoE Transceiver includes customer-driven features such as input and output status lights built into the device, eliminating the need for test or validation equipment; single fiber for send/receive, reducing required fiber and connectors by 50%; direct-connect fiber, with no SFPs required; power and status lights at the complementary headend equipment, simplifying post-install troubleshooting.

The IFP Connect PoE+ transceiver uses standardized IFP Connect wiring topology, simplifying prewires and allowing future upgrades without disturbing infrastructure cabling.

The product also allows a fiber-optic ecosystem to be installed at a lower cost than a traditional copper-based ecosystem. IFP Connect explains its hardware also reduces copper consumption by 19.3% vs. Category 6A, and by leveraging a fiber-optic network, an IFP ecosystem reduces carbon-dioxide output by 37% vs. traditional copper-based data networks.

The PoE+ Transceiver was developed directly from dealer input, feedback, and beta testing. This feedback was then leveraged, in combination with manufacturing partner involvement, to develop a product that fulfills the desires of the customer, while leveraging optimized manufacturing systems.

Let’s Talk Cabling

40-year industry veteran Chuck Bowser hosts the Let’s Talk Cabling Podcast. Born out of a desire to bridge the gap between knowledge and action, this podcast and multimedia platform is transforming how ICT professionals learn, grow, and connect. The podcast has over 300 episodes with over 180,000 monthly impressions across YouTube, TikTok, LinkedIn, and podcast platforms. Let’s Talk Cabling is the only program of its kind that reaches technicians, designers, project managers, and estimators, delivering expert content tailored to their evolving needs.

What makes this initiative innovative is its people-first approach to system design. The show isn’t just about interviews or product spotlights. It’s an agile, user focused platform that adapts to the real-time needs of the ICT workforce, offering practical "how tos", NEC and ANSI guidance, career strategies, and hard-earned field wisdom. The content is optimized for accessibility, reaching apprentices who may have a 10th grade education, as well as seasoned RCDDs and industry leaders. This wide appeal ensures the ROI for listeners is measured in job performance, confidence, and career growth. For employers, it translates to fewer callbacks, better workmanship, and a workforce that stays current with standards and trends.

Let’s Talk Cabling also addresses a critical industry challenge: knowledge loss due to retirement and turnover. By preserving and sharing expertise through audio, video, and live engagement, the show becomes a sustainable archive of industry best practices. It promotes lifelong learning without requiring costly classroom attendance or time away from the jobsite. From quick Lunchbox Learnables to deep dive interviews with subject matter experts, the content is curated with a lifecycle mindset training today’s workforce while preparing the next generation.

Leviton Network Solutions

FDT Category 6A F/UTP Cable. In June 2024, Leviton introduced its next generation Category 6A shielded cable, named FDT for Foil reduced Diameter Technology. This groundbreaking solution is not only the first filler-less Category 6A F/UTP cable, it also delivers the smallest outside diameter for a F/UTP CAT 6A cable on the market. This small outside diameter is created by Precision Twist Technology, a proprietary Leviton technology that precisely controls variation in the cable’s twist, enabling Category 6A performance in a much smaller form factor. This technology facilitates exceptional alien crosstalk performance, surpassing industry standards, all within a compact cable design.

It is this compact design that enables customers to decrease installation costs, leveraging smaller trays and conduits in new builds and reusing existing pathways that were originally designed for Cat 5e and Cat 6 cable. The cable is also available as part of the ATLAS-X1 FDT Cat 6A F/UTP MILLENIUM Global System

Features include a small outside diameter of 0.235 inches (5.97 mm), versus the average 0.270 (6.86 mm) Category 6A cable, along with a design enabling the cable to fit into pathways originally designed for Category 5e and Category 6 cables. Additionally, the filler-less construction reduces termination time and jobsite waste, while the CMP jacket is made with FLX-1 advance polymer technology for maximum flexibility, tighter bend radius, smoother pulls, and less installation stress.

The cable is available in riser, CPR, and LSZH constructions in addition to plenum. The LSZH and CPR-rated cables are manufactured in Leviton’s Glenrothes, Scotland carbon-neutral facility, while the plenum cables are manufactured in Leviton’s New Holland, Pennsylvania facility that is powered by emissions-free nuclear power.

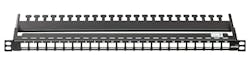

Half-RU Universal 24-Port Patch Panel. Leviton Network Solutions’ Half-RU Universal 24-Port Patch Panel addresses a growing challenge in modern networks. Increasingly, networks require higher density installations in environments like telecom rooms, entrance facilities, data centers, and consolidation points. Introduced in January 2025, the Leviton Half RU 24-Port Universal Patch Panel offers a global solution for dense racks and cabinets with an easy and efficient way to add network connections and reclaim rack space. Appropriate for both shielded and UTP applications, it provides EMI/RFI protection, signal isolation, and alien crosstalk supression. The low-profile panel is designed for racks or zone enclosures with limited usable space, applications where maximizing airflow through the back of the panel is a priority, and installations designed to optimize efficient scaling over time.

The universal panel works for both shielded and unshielded channels. A removable cable management tray is included, designed with cable singulation capabilities. The panels are compatible with all QuickPort and QuickPort-compatible jacks, allowing for a mix of copper and fiber connectivity. The panels are shipped in 100% recyclable packaging with no single-use plastics.

Panduit

A power distribution unit and two case-study application stories from Panduit earned honors in this year’s Cabling Innovators Awards program.

EL2P PDU. The Elevate to Power (EL2P) PDU represents a bold step forward in power distribution innovation, redefining how modern data centers manage, install, and secure critical infrastructure. Designed for performance-driven environments like colocation facilities, healthcare institutions, industrial settings, and higher education campuses, the EL2P blends forward-thinking design with practical application to solve the most pressing challenges in the evolving IT infrastructure landscape of today.

The EL2P PDU was built from the ground up in response to real-world customer pain points. Through direct feedback loops and hands-on collaboration with installers, operators, and IT managers, Panduit identified key friction points in traditional PDU design; namely, complex installation requirements, visibility challenges, limited adaptability, and growing security demands. In response, the EL2P Series introduced a 360° swivel inlet that accommodates both top- and bottom-fed installations with ease, drastically reducing cable bending radius and making it more ergonomic and intuitive to connect in tight spaces.

The integrated auto-rotating display, powered by an onboard accelerometer, is another industry-driven innovation, automatically adjusting screen orientation based on mounting position. This eliminates the need for repositioning during installation and ensures real-time data is always readable at a glance. This is not just a convenience, it is a workflow efficiency enhancement that reduces install time and errors.

The EL2P uses tool-less mounting, intelligent UI, and simplified configuration deliver significant ROI. Install times are reduced significantly, configuration time happens in a matter of seconds vs 10-15 minutes with one-touch provisioning, and field teams experience fewer call-backs due to installation errors. These savings ripple through the organization from operations to procurement, freeing up technical teams for higher-value tasks and reducing total cost of ownership.

Every feature of the EL2P is rooted in solving real issues: “Outlets are hard to see.” “Installs take too long.” “Updates are painfully time-consuming.” These insights from field professionals shaped the product. The result is a solution that does not just perform, it solves. The EL2P delivers visibility through brightly labeled outlets and a user-centric interface; it speeds installation through innovative physical design; and it simplifies updates through automated provisioning and secure firmware syncs.

Rockford Public Schools Case Study. Rockford Public Schools, one of Illinois’ largest districts, has partnered to proactively modernize its infrastructure, laying the groundwork for long-term success. This initiative is poised to set new benchmarks across the education industry, aligning with the district’s strategic priorities around academic excellence, sustainability, and community impact. Faced with outdated systems, cybersecurity vulnerabilities, and inconsistent IT standards across the district, Rockford Public Schools recognized the need for a modern infrastructure overhaul to get back on course. A 2019 ransomware attack served as one of the prominent reasons that highlighted the importance of staying current with cybersecurity strategies and implementing secure, reliable solutions. As part of the response, the district aligned its efforts with the NIST Cybersecurity Framework, establishing a resilient infrastructure that not only met today’s demands but was also ready for future challenges.

A key objective was to transform its data center infrastructure to meet Tier 3/4 standards. To achieve this, the district implemented innovative solutions from Panduit—including FlexFusion™ Cabinets, Intelligent Power Distribution Units, structured cabling, and the Net-Contain™ Aisle Containment System. Leveraging ICEcad drawings, the team was able to visualize and fine-tune the design before deployment, ensuring a transition from concept to completion. It has delivered measurable results across multiple departments at Rockford Public Schools. By standardizing IT infrastructure across all 41 schools, the district has enhanced operational efficiency, reduced troubleshooting time, and significantly lowered maintenance costs. The integration of RapidID™ labeling and QuickNet™ patch panels has helped minimize downtime, ensuring nearly zero disruption to the district’s 27,000 students. With support for Wi-Fi 6 and readiness for emerging technologies like AI, the new infrastructure is built for long-term ROI and future scalability.

Rockford Public Schools stands out as a leader both in its local community and among school districts nationwide. Through the new modern infrastructure, they will be able to ensure reliable internet access, enabling equitable learning opportunities. With its new infrastructure in place, Rockford Public Schools continues to strengthen its commitment to students and their future. The upgraded environment offers students exposure to real-world IT systems, equipping them with hands-on experience and preparing them for careers in technology. With Microsoft building a nearby data center, their students are positioned to benefit from hands-on learning and future employment opportunities.

The project’s success stemmed from strong collaboration between Rockford Public Schools, the Panduit team, including engineers, and Graybar’s distribution network. Board of Education support and cross-functional teamwork from IT staff to educators played a critical role in keeping the project on track and delivering impactful results. Rockford Public Schools’ data center modernization is a great example of how innovative products and solutions, including cabling, can drive educational excellence, and operational efficiency. The work that has been completed so far demonstrates how strategic planning paired with the right products and solutions can not only lay the groundwork for future success but also set a new benchmark for innovation in the education industry.

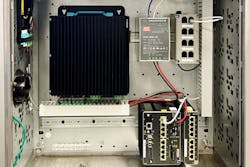

Miller Electric Company’s Deployment of the Panduit Fault Managed Power System. Miller Electric Company, a leading electrical contractor and long-standing Panduit Partner, faced a daunting power distribution challenge. The project required installing cameras, distributed UPSs, PoE switches, and media converters across several 85,000 sq. ft. buildings, with the nearest power source located over 1,000 feet away. Traditional approaches would have required new electrical panels, extensive conduit pathways, and disruptive power shutdowns—dramatically increasing project complexity, timeline, and costs. The installation team needed an innovative solution that could extend power across vast distances while minimizing operational disruptions.

The Panduit FMPS provided the breakthrough solution. This market-first system offers:

• UL 1400-1 Standard Compliance: The only Class 4 power system meeting this rigorous safety standard

• Extended Power Distribution: Capable of powering devices over 1,000 feet from source

• Integrated Solution: Complete ecosystem including UPSs, PDUs, copper and fiber connectivity, racks, and cable management

• Minimal Disruption: Designed for installation with reduced shutdowns

"The most compelling factor was that it is UL-certified," said Chris Cuyler, Senior Project Manager at Miller Electric. "That gives me the confidence to install a system which I know is vetted, tested, and approved to meet that standard." The system's capabilities were particularly evident in a critical airfield application, where high-resolution Avigilon cameras needed installation across a thousand-foot building—far exceeding standard Ethernet limitations of 100 meters. The FMPS enabled Miller Electric to successfully power these security cameras over extended distances while maintaining signal integrity and system reliability.

Patton Electronics Co.

Patton Electronics Co. describes its CopperLink Ethernet Extender as the “world’s smallest” Ethernet extension device. The SFP module extends Ethernet up to 3.5 miles over copper and achieves speeds up to 18 Mbits/sec. The CL-SFP is a small-form pluggable (SFP) Ethernet extender that the company says seamlessly integrates with routers, Ethernet switches, and media converters. It extends Ethernet connections up to the aforementioned 3.5 miles with data rates as high as 18 Mbits/sec, which Patton says is an ideal alternative to new fiber installations.

Designed to fit into standard SFP slots, the CL-SFP easily integrates with existing equipment and enables quick deployment while reducing installation costs. It provides network extension in a variety of environments, including industrial, government, commercial, and residential. Its robust design makes it suitable for applications in military, transportation, energy, heavy manufacturing, and other mission-critical industries.

Siemon

Two innovative products and two application case studies from Siemon earned honors as Cabling Innovators Awards recipients.

Nicklaus Children’s Hospital. Constructing the Griffin Surgical Tower presented unique challenges for Nicklaus Children’s Hospital due to the lack of available space on the existing landlocked campus. They ultimately decided to construct the tower atop the existing emergency department, which required relocating the helistop pad. Despite these obstacles, the new tower’s design incorporates thoughtful features such as a unique glass sculpture in the main lobby that spans three levels, an outdoor Healing Garden Plaza, a fourth-floor outdoor terrace area, and a sixth-floor Wonder Room for children’s activities. The new tower’s second and third floors feature multiple operating rooms equipped with augmented and virtual reality collaboration platforms, robotic surgery, and other advanced technologies that improve patient care and efficiency. Family and waiting areas offer secure Wi-Fi and entertainment, and each room allows patients and visitors to stay connected and informed through the hospital’s GetWellNetwork® service that provides email and child-safe internet access, educational information, entertainment, and information on hospital programs and services. Nicklaus Children’s has also adopted AI-enabled radiology workflow solutions for faster diagnosis and treatment and a range of patient experience technologies like dynamic lighting, video projection, soothing sounds, and even a miniature scanner to prepare children for upcoming MRI or CT procedures in a playful way.

The hospital needed a robust network to support the latest healthcare technologies in the new tower while ensuring support for future technologies to meet the evolving needs of pediatric care for decades to come. The tower’s 100-Gigabit fiber backbone infrastructure consists of 96-strand singlemode fiber cables running from two main equipment rooms to each of the eight telecom rooms, with an additional 96 strands deployed between the rooms for redundancy. Additionally, 576 strands of OM4 multimode fiber were installed in the operating rooms, bringing the total number of fiber fusion splices to 3,456. Each floor features a 10-gigabit network using Category 6A copper cabling to provide connectivity and power to various devices. The infrastructure includes anywhere from 8 to 16 connections per room.

When it came time to select the components for the surgical tower network, Nicklaus Children’s Hospital preferred to use solutions from their longstanding infrastructure solutions provider, Siemon. For over a decade, Siemon has provided the hospital with a wide range of high-performance fiber and copper connectivity and cable management solutions to support the latest healthcare technologies. Siemon’s customer service, technical support, logistics, and supply chain capabilities, backed by a dedicated distribution and certified installer partner ecosystem, were also a big plus for the hospital.

Siemon’s investment in research and development has led to innovative solutions that benefit customers. These solutions helped Nicklaus Children’s Hospital improve system performance and reduce installation costs. With over 400 patents specific to structured cabling and world-class ISO-certified manufacturing, Siemon has released over 20 new products within the past five years to fit customer needs and applications.

One of the latest Siemon innovations deployed for the fiber backbone infrastructure at the Griffin Surgical Tower is the LightVerse® High-Density Fiber Optic Cabling System. Available in 1U, 2U, or 4U, the LightVerse Pro version chosen by Nicklaus Children’s supports up to 48 duplex singlemode fiber ports in 1U with integrated front and optional rear cable managers, cable strain relief brackets, multiple cable entry points, and an integrated label holder. LightVerse is versatile and offers various options for design and installation. These options include transition modules, adapters, and splice solutions that support multiple connector types and any termination method. The hospital used LightVerse Splice Cassettes that support up to 24 fibers with pre-loaded adapters and color-coded pigtails. The cassettes can be easily installed from the front or rear of the LightVerse enclosures.

UNC Health. At UNC Health, a primary challenge was to create an infrastructure capable of supporting various applications, including VoIP, PoE, AV, security, wireless, and building automation. The objective was to outfit the facility with a modern technology infrastructure. This included enhanced bandwidth, integrating state-of-the-art systems and applications, and ensuring seamless connectivity across the facility.

UNC Health’s stringent requirements for high-quality products led to the selection of Siemon. As a Siemon-certified installer, Trident Technology Solutions was wellequipped to meet these standards. Siemon’s reputation for reliability, compliance, ease of installation, technical support, competitive pricing, and warranty were key decision factors. Siemon’s Category 6 UltraMAX™ outlets, in particular, were chosen for their efficient design and ease of installation, which proved to be a significant time-saver for technicians. Siemon products were chosen exclusively, as UNC Health’s ISD specifications mandate the use of Siemon products for all new installations. This ensured consistency and reliability across the facility’s network infrastructure.

The project involved the installation of horizontal and backbone cabling, utilizing Siemon products. The infrastructure included a newly built MDF (Main Distribution Frame) and 33 additional IDF (Intermediate Distribution Frame) and EIDF (Equipment Intermediate Distribution Frame) rooms. The infrastructure supported various applications, including VoIP, PoE, AV, security, wireless, and building automation. This support ensured that all technological needs of the healthcare facility were met, providing a solution that could handle current and future demands. At the beginning of the installation, one of the initial hurdles was familiarizing technicians with the termination process of the new UltraMAX™ outlet. Technicians quickly found the UltraMAX outlet was easy to use and efficient, significantly reducing termination time. The punch-down termination module allowed cables to dress from both sides of the outlet allowing cables to flow neatly into cable managers. In addition, UltraMAX outlets can be mounted from the front or rear of a faceplate, enabling installers to terminate and insert outlets into the faceplate once already secured to the wall, simplifying the process. The UltraMAX TurboTool helped to accelerate project completion by enabling installers to quickly terminate thousands of connections, saving hundreds of labor hours.

Post-installation, the network underwent rigorous testing and was found to be error-free. The comprehensive testing ensured that the infrastructure met all performance criteria, guaranteeing reliability and stability for UNC Health’s critical operations. The project was completed successfully, with the network running smoothly and as expected.

Bundled fiber trunks. Designed to streamline fiber optic network installations and reduce deployment time, Siemon Bundled Fiber Trunks offer a cost-effective and reliable option for a variety of projects. They combine high-performance fiber cables into a single, easy-to-manage bundle, optimizing pathway fill and significantly accelerating installation. With up to a 50% faster deployment rate, this innovative solution helps businesses and organizations reduce project costs and time-to-market.

Key features include the following.

·Streamlined installation: Reduced pathway fill and faster deployment

·Exceptional performance: Equivalent to single-jacket fiber

·Durability: Robust construction for reliable performance

·Versatility: Available in a wide range of configurations

High-Density 800G Cable Assemblies. Siemon’s comprehensive portfolio of flexible Direct Attach Copper (DAC) and Active Copper Cable (ACC/AEC) assemblies were developed for high-speed switch-to-switch and switch-to-server/storage applications. Supporting Ethernet and InfiniBand™ at speeds up to 800G, these cables are designed to optimize performance and simplify cable management in today’s demanding data center environments.

Siemon’s DAC and active copper cable assemblies demonstrate the company’s commitment to high performance, reliability, and best-in-class cable management. These assemblies are rigorously tested for interoperability, performance, and signal quality at PAM4 speeds and are compatible with OSFP, QSFP-DD, QSFP, SFP DD, and SFP112 connectors. This new generation of DAC and active copper cables represents a significant leap forward in cable design. They enable low-power, low-latency copper cable deployments at next-generation 800G network speeds. With a smaller bend radius and 40% smaller cable diameter compared to traditional jacketed cable, Siemon is simplifying 800G deployments.

Sticklers Fiber Optic Cleaners

The Sticklers™ Pro360°™ Touchless Cleaner stands out as a groundbreaking advancement in fiber optic end face cleaning—bringing true innovation to a long-overlooked but critical part of cabling infrastructure maintenance. This revolutionary tool ends the inconsistencies, inefficiencies, and environmental challenges of traditional cleaning methods with a precise, touch-free approach that protects critical infrastructure, reduces operational costs, and advances sustainability across the telecommunications industry.

Traditional connector cleaning methods—such as solvent-soaked wipes, click-to-clean tools, or foam swabs often introduce contamination, and risk end-face damage due to operator error. In contrast, the Pro360°™ uses the Coanda effect, a scientific principle that harnesses fluid dynamics, to evenly deliver a micro-dose of atomized cleaning fluid across the end face of a connector. This contactless spray-and-vacuum method provides consistent, repeatable, and lab-verified cleaning performance in just seconds. The precision-engineered system ensures thorough particulate and oil residue removal without ever touching the delicate connector surface.

In an industry increasingly focused on environmental impact, the Pro360™ excels in sustainability. Its proprietary Sticklers™ cleaning fluid is nonflammable, low VOC, and specifically engineered for high-purity cleaning without ozone-depleting substances. By eliminating wipes and minimizing solvent usage, it significantly reduces the carbon footprint associated with fiber cleaning—making it a cleaner tool in every sense of the word.

The Pro360°™ was designed in direct response to a critical industry pain point: the need for consistent, safe, and reliable cleaning of fiber end faces, especially in environments where human error, harsh weather, or high-volume demands can compromise quality. Pro360°™ was conceived and executed to solve these issues with precision engineering, rigorous testing, and real-world validation. Its intuitive operation and unmatched repeatability allow even junior technicians to achieve expert-level cleaning results, leveling the field in terms of workforce experience and reducing the training burden for employers.

By setting a new benchmark for fiber connector cleaning, the Sticklers™ Pro360°™ Touchless Cleaner enhances overall network reliability, reduces maintenance costs, and contributes to safer, cleaner installations. It empowers technicians, supports sustainability initiatives, and helps future-proof fiber networks as demand for data continues to grow.

STL – Sterlite Technologies Ltd.

Multicore Fiber. STL describes its Multicore Fiber as “more than a technology upgrade. It’s a shift in how we think about networks. With four transmission cores in one fiber, it delivers 4x the capacity without expanding your duct or footprint. This means network builders can scale faster, cheaper, and smarter, especially when every millimeter matters in data centers, AI workloads, and 5G edge buildouts.” STL emphasizes the following characteristics and capabilities of its multicore fiber.

·Handles quantum-safe signals and classical data together

·Maintains < -45 dB crosstalk for reliable performance

·Is compatible with existing G.652D fibre networks

·Is already lab-validated, field-tested, and deployment-ready

To make this innovation real for customers, STL developed a full suite of cables incorporating the multicore fiber. Those cables are:

·MCF Armored Cable—Tough and reliable for rugged terrains, ideal for railways, metros, and harsh industrial zones

·MCF ADSS Cable—Lightweight, aerial, and self-supporting, perfect for fast overhead deployments near power lines

·MCF Unitube Armored Cable—Compact and durable, built for buried or duct networks in tight, high-demand environments

·MCF Unitube ADSS Cable—Slim, aerial-ready design for quick rollouts in rural broadband and utility corridors

STL demonstrated multicore fiber at several proving grounds, including IIT Madras, one of India’s most advanced AI network testbeds. Across underground ducts, aerial paths, and tight city loops, STL’s multicore fiber cables delivered seamless integration, clean fanouts, and consistent performance. Additionally, STL’s multicor fiber successfully transmitted quantum keys and regular data over more than 100 kilometers on the same fiber, at the same time, in India’s first quantum-safe transmission trial.

Aerial Fiber Distribution Hub. STL’s Aerial Fiber Distribution Hub (A-FDH) is purpose-built for overhead networks. It mounts directly to the messenger strand of existing aerial infrastructure using a robust offset bracket, eliminating the need for ground space or permitting delays associated with traditional cabinets. This design makes it ideally suited for aerial installations in towns, suburbs, and rural areas where pole infrastructure already exists but ground installations are not viable. By hanging securely to a strand instead of directly on a pole, the A-FDH avoids pole attachment fee complications, minimizes environmental exposure, and speeds up installation without compromising network performance.

STL’s A-FDH uses an adjustable aerial bracket that secures the hub at four mounting points. This streamlined installation reduces labor time and avoids delays tied to ground disturbance, trenching, or concrete work, enabling weeks of time savings per site. Alternatively, it is also designed to be mounted on the ground in a typical “dog house” style pedestal. Each unit comes with factory-terminated 100-foot feeder and distribution cables, using 12, 24, or 48-fiber IBR (Intermittently Bonded Ribbon) construction. These all-dielectric cables are pre-tested for performance, simplifying field connections, speeding up installation via mass fusion splicing option, and reducing skilled labor dependency.

Available in 144- or 288-port configurations, the A-FDH supports both centralized and distributed split architectures with 10 splitter slots and 1x32 splitters (factory-installed or customer-loaded). The built-in fiber parking lot supports up to 64 fibers for easy reconfiguration.

Trend Networks

As enterprise and campus networks evolve to support higher bandwidth, lower latency, and denser device deployments, 10 Gigabit Ethernet is quickly becoming the new standard for LAN infrastructures. At the same time, the demand for fiber backbones and reliable Wi-Fi performance is accelerating. The SignalTEK QT Series addresses these challenges head-on, offering a comprehensive, cloud-connected tester that ensures installed infrastructure is ready for todays and tomorrow’s digital requirements. It provides the following capabilities.

• Copper cable qualification from 10Mb/s up to 10Gb/s, including 2.5Gb/s and 5Gb/s Multi-Gig, with RF testing for NEXT, return loss, and insertion loss

• Fiber qualification up to 100Gb/s (QT Pro), measuring insertion loss and length to IEEE standards using loopback testing and high-performance SFP modules

• Wi-Fi diagnostics to identify overlapping access points, analyze channel utilization, and troubleshoot active connections with tools like ping, traceroute, and device scans

• PoE load testing up to 90W to confirm adequate power delivery for the latest connected devices

At the heart of the SignalTEK QT Series is its integration with TREND AnyWARE Cloud, enabling seamless communication and project management across teams. With this platform, users can:

• Upload, store, and share test results securely from any device

• Attach project files, diagrams, and photos to ensure all data is stored in one location

• Pre-configure jobs remotely, eliminating technician setup errors

• Provide real-time remote support via TeamViewer or VNC, reducing costly site revisits

• Keep fleets of testers up to date with over-the-air software updates

The intuitive touchscreen interface simplifies setup and operation, while integrated tools such as a visual fault locator, live wiremap, and fiber inspection microscope support (available on the QT Pro) enable technicians to identify and resolve issues faster. A high-capacity Li-Po battery provides up to 10 hours of operation, ensuring the tester lasts through long workdays. The inclusion of external WiFi antenna support allows technicians to locate hidden access points and extend range during site surveys - an invaluable feature in increasingly complex environments.

Wirewerks

Wirewerks’ Fiber Deployment Panel (FDP) System is a 1U high-density fiber patch panel system designed to dramatically simplify and accelerate fiber deployment/distribution in data center, headend, central office, PON, and LAN environments/applications. The FDP System is a complete factory-kitted, factory-terminated fiber distribution system that provides ultra rapid-deployment, plug-and-play fiber distribution solutions in high fiber-count, high-density optical network environments. Each FDP System is a factory-kitted solution that includes a 1U Fiber Distribution Panel (FDP) complete with spooled, factory-terminated MPO/MPO fiber cable assemblies, and a corresponding Fiber Termination Panel (FTP) with integrated storage capacity/slack management for the incoming MPO cable assemblies.

Technicians simply unspool the onboard fiber cable assemblies from the Fiber Deployment Panel (FDP), pull to the Fiber Termination Panel (FTP), click-connect the low-loss MPO connectors and store/manage any cable slack within the FTP itself. The entire fiber path is field-splice-free with plug-and-play low-loss MPO connectivity for fast, reliable deployments using fewer fiber-specialist technicians. Each FDP is equipped with 2 onboard cable spools, with each holding 30m of 48F high-density, mini-distribution cables for 96F-LC port configurations, or 30m of 72F high-density, mini-distribution cables for 144F-CS port configurations. The standard 30m-reach satisfies >94% of applications surveyed, and FDPs may be ordered with custom cable assemblies up to 200m or more, shipped on external cable spools, if/when required. Each FTP includes integrated cable storage capacity for slack management of incoming cable assemblies. This allows techs to easily accommodate cable slack at the termination end, keeping cables neat and organized while reducing congestion in cable trays/pathways.

Wirewerks attests, “Our lead development partner for the FDP System—one of the country’s largest services providers—confirms that: 1) The tech-friendly ‘easy-access’ design, the onboard ready-to-deploy fiber trunks, and the integrated cable storage/slack management features allow their technicians to complete installs in 60 to 90% less time compared to traditional fiber patch panel deployments; 2) 100% factory-terminated and tested plug-and-play connectivity increases network performance and reliability while reducing requirements for hard-to-find specialist techs at the same time; 3) The System’s use of high-density, mini-distribution cables versus typical 12-fiber cable assemblies reduces cable congestion by up to 25% in cable trays and pathways.”