A new technical document from OFS covers the basic guidelines for installation of fiber-optic cable in underground plant.

The guide outlines best practices for cable placement in conduit, innerduct, handholes, and manhole structures and is intended for use by personnel with prior experience in planning, engineering, or placement of underground cable. (A working familiarity with underground cable requirements, practices, and work operations is necessary, as the guide does not cover all aspects of underground construction work.)

The 22-page document covers conventional cable placement techniques that are used to pull or blow (via cable jetting) the cable into the conduit or innerduct. OFS notes that innerduct may be direct buried or placed in larger diameter conduits. Or in some applications, the innerduct may be lashed to an aerial strand.

The guide opens by describing 5 general rules for placing fiber-optic cable in underground plant. Directly quoting from the guide, these general rules are as follows:

1. Conduct Route Survey and Inspection

"It is recommended that an outside plant engineer conduct a route survey and inspection prior to cable installation. Manholes and ducts should be inspected to determine the optimum splice locations and duct assignments. A detailed installation plan, including cable pulling or blowing locations, intermediate assist points, and cable feed locations should be developed based on the route survey."

2. Check for Maximum Rated Cable Load

"The maximum rated cable load (MRCL) for most OFS outside plant fiber optic cables is 600 lb; however, the cable documentation should always be checked, because lower values of MRCL may apply for some cables. When using pulling equipment to install cable, measures should be taken to ensure that the MRCL is not exceeded. This includes the use of breakaway swivels, hydraulic pressure relief valves, and electronic tension control systems."

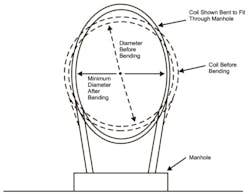

3. Define Minimum Bend Diameter

"The minimum bend diameters for OFS cables are defined for both dynamic and static conditions. The dynamic condition applies during installation when a cable may be exposed to the MRCL, e.g., while pulling the cable around a sheave or capstan."

4. Observe Temperature Limits

"Storage and installation of OFS fiber-optic cable is limited to the temperature ranges. Be aware that solar heating due to sunlight exposure can increase the cable temperature well above the ambient temperature."

5. Guarantee Underground Optical Cable Precautions

"Before starting any underground cable placing operations, all personnel must be thoroughly familiar with local company safety practices. Practices covering the following procedures should be given special emphasis:

Innerduct

Cable Lubricant

Cable Placing Methods

Pulling Fiber Optic Cable

Blown Optical Cable Installation

Optical Cable Coiling

Racking Fiber Optic Cable and Innerduct

View/Download the full guide (PDF) for more information describing each of the listed procedures.

About the Author

Matt Vincent

Senior Editor

Matt Vincent is a B2B technology journalist, editor and content producer with over 15 years of experience, specializing in the full range of media content production and management, as well as SEO and social media engagement best practices, for both Cabling Installation & Maintenance magazine and its website CablingInstall.com. He currently provides trade show, company, executive and field technology trend coverage for the ICT structured cabling, telecommunications networking, data center, IP physical security, and professional AV vertical market segments. Email: [email protected]